AS-III

More

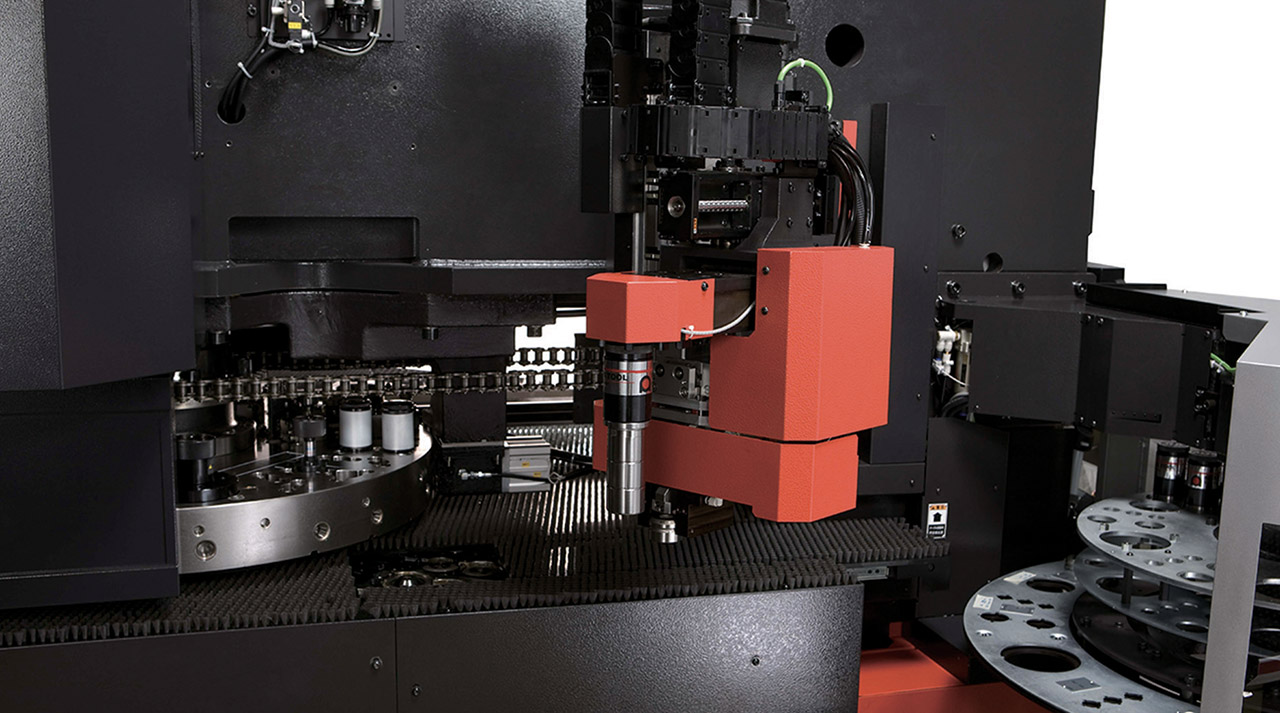

The EM-ZR range is equipped with an unrivalled dual servo motor drive system and AMADA’s unique ZR turret - a highly innovative feature for turret punching machines. With the automatic Tool Storage Unit (TSU) and digital tool management (AMADA ID Tooling System-AITS), the EM-ZR range is ideal for the continuous manufacturing of small, variable lots.

AUTOMATIC SETUP:

Tools can be changed while the machine is operating, maximising productivity.

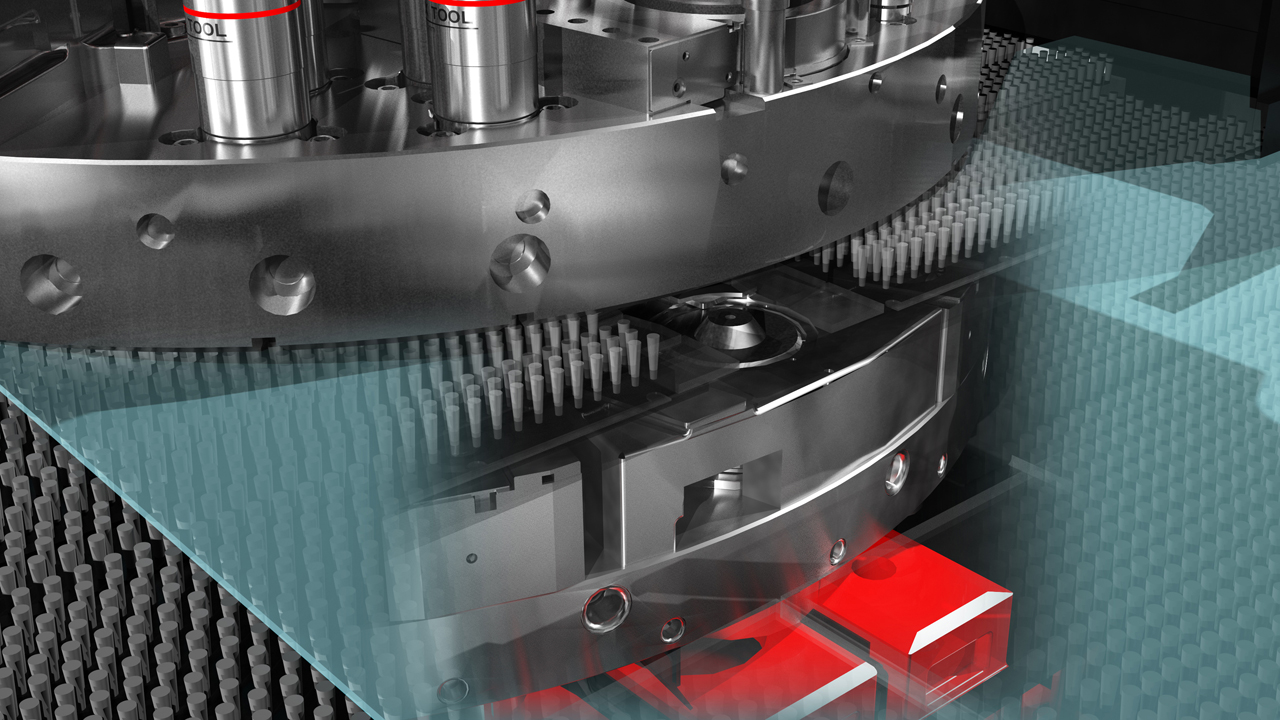

QUALITY PROCESSING:

Featuring a scratch-preventing turret, covered with a brush table and dies that lift only when actually used, this machine will provide top-quality parts.

ERROR PREVENTION:

With the AMADA ID Tooling System (AITS), setup errors are avoided, and damage prevented.

| EM-3510ZRB | EM-3612ZRB | EM-3510ZRT | EM-3612ZRT | |

|---|---|---|---|---|

| Press capacity (kN) | 300 | 300 | 300 | 300 |

| Positioning accuracy (mm) | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 |

| Number of stations | 32 | 32 | 32 | 32 |

| Tool buffer system | 33 | 33 | 300 | 300 |

| Machine frame | Bridge frame | Bridge frame | Bridge frame | Bridge frame |

| Axis travel distance (mm) | 2500 x 1275 | 3050 x 1525 | 2500 x 1275 | 3050 x 1525 |

| Machine table type | Brush table | Brush table | Brush table | Brush table |

Dimensions: | ||||

| Length (mm) | 6157 | 6582 | 7005 | 7415 |

| Width (mm) | 5120 | 6220 | 5120 | 6220 |

| Height (mm) | 2367 | 2367 | 2666 | 2666 |

| Weight (kg) | 20000 | 21500 | 23500 | 25000 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.