In the sheet metal processing landscape, combination machines represent a concrete response to the need to reduce production steps, optimize lead times, and increase operational flexibility.

The EML-AJe + PDC solution was developed with precisely this goal: to integrate punching and laser cutting into a single high-efficiency platform capable of handling complex operations while maintaining high standards of quality, productivity, and cost control.

FULLY ELECTRIC TECHNOLOGY AND ENERGY SAVINGS

One of the distinctive features of the EML-AJe is its fully electric punching system, based on AC servo motors capable of generating up to 30 tons of force.

This solution reduces energy consumption by up to 70% compared to traditional hydraulic systems, while maintaining high performance levels. The internally developed 3 kW AMADA fiber laser also contributes to lower operating costs, making the machine particularly suitable for efficient and sustainable production.

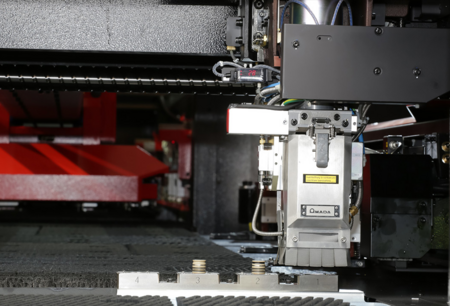

INTEGRATED TECHNOLOGIES FOR AUTONOMY AND OPERATIONAL CONTINUITY

The EML-AJe integrates a range of solutions designed to increase machine autonomy and reduce operator intervention. The Laser Integration System coordinates automatic functions such as nozzle control and process monitoring, while the Automatic Nozzle Changer ensures fast replacement and uninterrupted operation. To support daily operations, the V-monitor system enables real-time machine status monitoring and simplifies diagnostics in the event of alarms, improving production management even remotely.

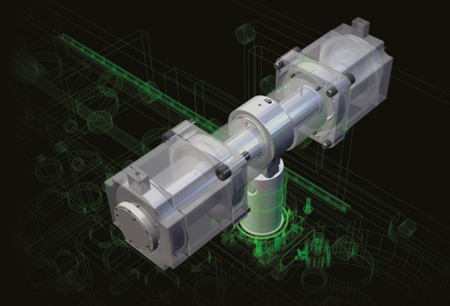

AUTOMATIC PDC TOOL CHANGER: FLEXIBILITY WITHOUT COMPROMISE

The integration of the PDC (Punch Die Changer) unit represents a further step forward in automation. The system automatically manages the loading and unloading of punching tools, minimizing manual operations. With a capacity of up to 220 punches and 440 dies, the PDC allows highly diversified production without interrupting the production cycle, significantly increasing flexibility and reducing setup times.

AMNC 4ie NUMERICAL CONTROL: SIMPLICITY AND DIGITAL INTEGRATION

The entire system is managed by the AMNC 4ie numerical control, designed to offer an intuitive interface and advanced operator support tools. The high-definition touch screen display, integrated assistance functions, and connection to AMADA digital systems enable optimized machine management and reduced downtime. Integration with the AMADA software ecosystem makes the EML-AJe + PDC a solution ready for increasingly connected, Smart Factory-oriented production.