The new EGB-6013ARce robotic bending cell is the natural evolution of the compact EG-6013AR, with expanded capacity and smaller footprint. Equipped with the new EGB-6013e servo-electric bending press brake, this new bending cell specialises in the production of small, complex components, but with the flexibility to also produce parts up to 550x300mm.

The perfect solution to increase the production output of difficult-to-produce parts.

The easy effective operation of the robotic cell gives maximum production output with minimum operator input. By using the smart functions such as Tablet HMI and automated teaching, the need for a skilled operator is removed.

In addition, faster part handling, an increased tool library, greater loading capacity and a larger range of grippers give increased flexibility to this machine.

FAST, PRECISE, EFFICIENT

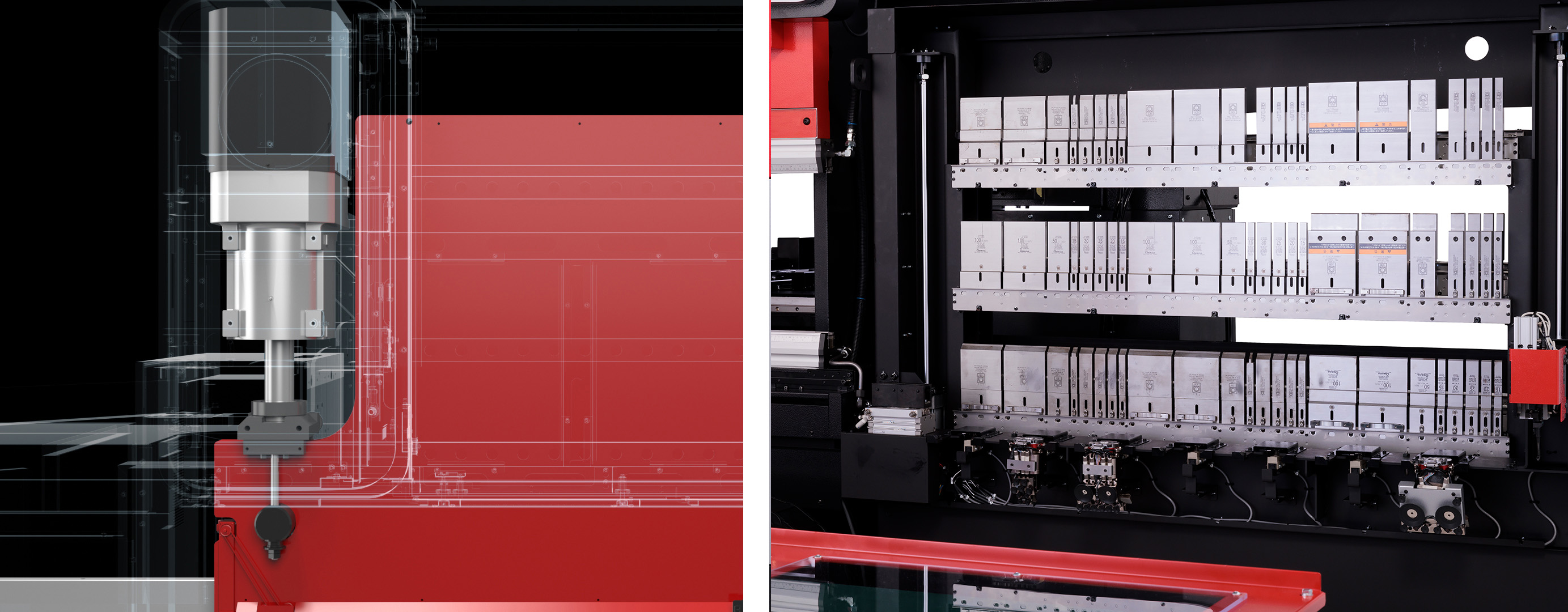

A new servo-electric technology offering top performance and accuracy.

The ATC by AMADA minimizes tool set-up times, making it ideal for small batches and rush jobs.

EASE OF USE:

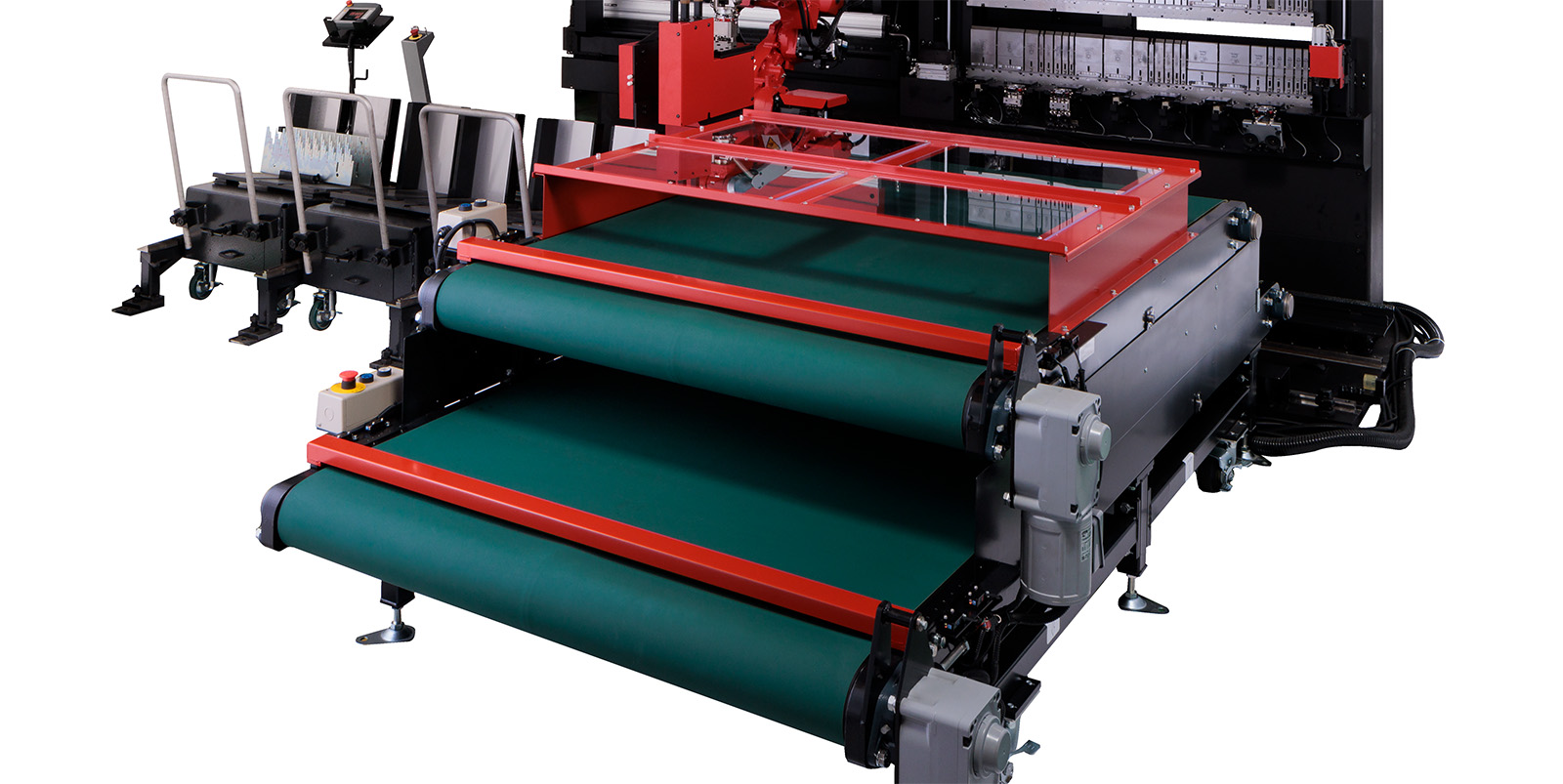

Loading and unloading automation bring ureveilled autonomy and easy of use it.

PRODUCTIVE:

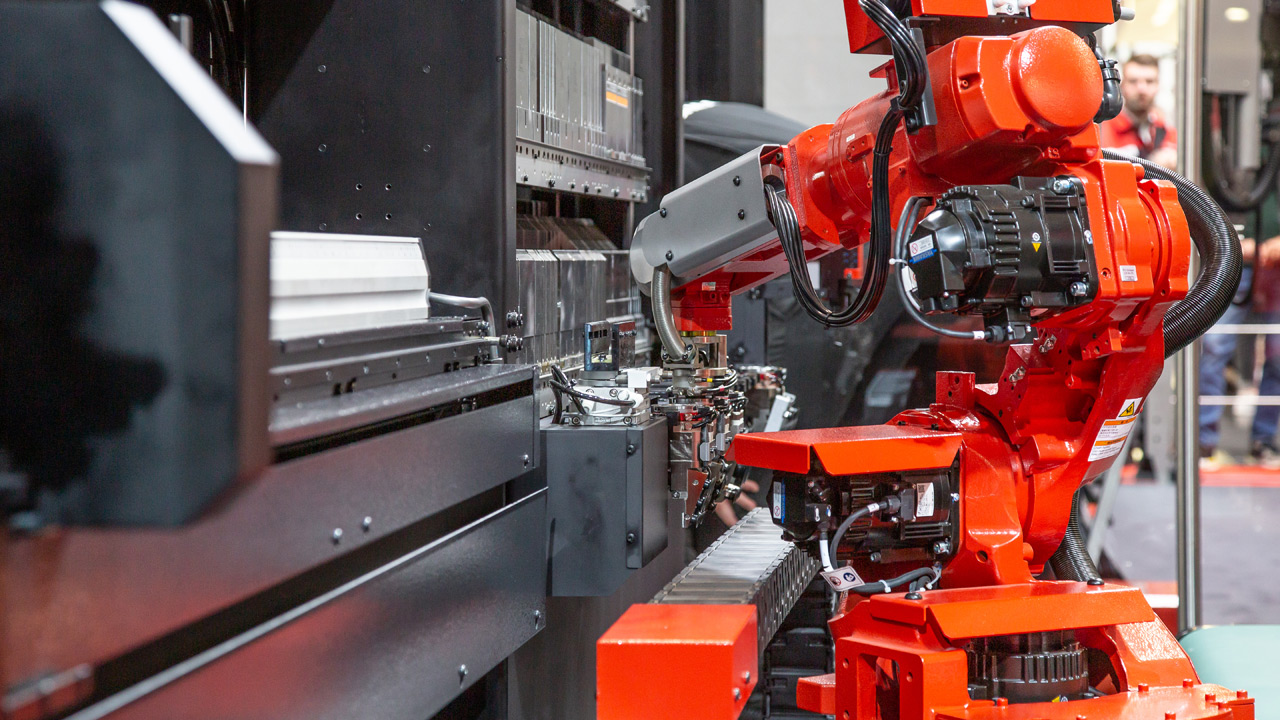

A six-axis robot on a travelling axis; compact and faster than ever, with optimised movements to further improve the cycle time.

| EGB-6013ARce | |

|---|---|

| Numerical Control | AMNC 4ie |

| Press capacity (kN) | 600 |

| Max. tool layout length (mm) | 1160 |

| Distance between frames (mm) | 1010 |

| Open height (mm) | 585 |

| Stroke (mm) | 150 |

| C-throat (mm) | 230 |

| Oil capacity (l) *except for AMTS III S clamping system | 0* |

| Approach speed (mm/s) | 250 |

| Bending speed (mm/s) | 25 |

| Return speed (mm/s) | 250 |

| Number of axis | 9 |

ATC - tool changer: | |

| Tool holder | AMTS III |

| Max. number of tool types | 27 |

AGC - gripper change: | |

| Max. gripper capacity * one slot reserved for the tool gripper | 8* |

Robot: | |

| Robot Manufacturer / Model | Yaskawa EGBRBT010E |

| Robot Payload, including gripper (kg) | 10 |

| Travel axis length (m) | 3.2 |

| Loading areas | 3 |

| Loading max. position per area (with LD camera) | 2 |

| Unloading areas | 2 on Belt conveyor |

| Workpiece min dimensions (mm) | 80 x 30 |

| Workpiece max dimensions (mm) | 400 x 400 or 550 x 300 |

| Thickness range (mm) | 0.5 – 6.0 |

Dimensions: | |

| Length (mm) | 4620 |

| Width (mm) | 3865 |

| Height (mm) | 2630 |

Some devices of functions could be available as option or separately from the machine.

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.