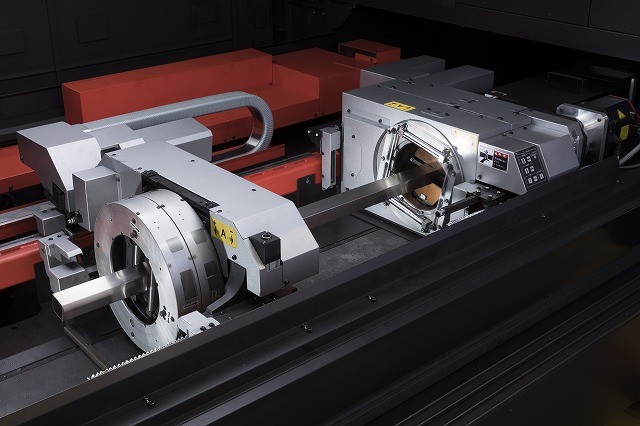

AMADA je kombinovala dve jedinstvene tehnologije kako bi vam pružila krajnju fleksibilnost kada je u pitanju obrada čelika. ENSIS tehnologija za kontrolu laserskog snopa i dokazani sistem Rotacionog indeksa za sečenje cevi kombinovani su u mašini koja može da ispuni širok spektar proizvodnih zahteva. Sve sa jednom mašinom, uz niže troškove i maksimizovanje vaše produktivnosti.

FLEXIBILITY:

The ENSIS-RIe can process round, square and rectangular tubes as well as channel and angle profiles. Thanks to a single cutting lens and automatic nozzle changer, all materials, thicknesses and profiles can be processed with minimal setup.

V-MONITOR

Access to the latest production status of mulitple machines is provided by V-monitor, as is the ability to view HD video of production issues, allowing fast response from AMADA's IoT support network.

QUICK TRANSITION FROM SHEET METAL TO TUBES:

With the ENSIS-RIe, the transition from processing sheet metal to tubes is quick and simple, with setup taking as little as 5 minutes.

| ENSIS-3015RIe | |||

|---|---|---|---|

| Snaga lasera (W) | 3000 | 6000 | 9000 |

| Tip mašine | Fiber laser mašina za sečenje | ||

| Radni opseg X x Y (mm) | 3070 x 1550 | ||

| Radni opseg Z-ose (mm) | 200 | ||

| Ponovljivost preciznosti (mm) | ± 0.01 | ||

| Nosivost stola (kg) | 920 | ||

| Pogonski sistem | Spiralni nosač i zupčanik | ||

Specifikacije Rotary Index-a*: | |||

| Okrugla cev Ø (mm) | 19 - 220 | ||

| Četvrtaste cevi (mm) | 19 - 150 | ||

| Prečna dijagonala višeugaone cevi (mm) | 220 | ||

| Profil kanala (mm) | 19 - 150 | ||

| Ugaoni profil (mm) | 19 - 130 | ||

| Maksimalna težina cevi (kg) | 200 | ||

| Maksimalna dužina cevi (mm) | 6000 | ||

| Cev / Debljina zida preseka (mm) | 1 - 9 | ||

| Ugao / Debljina zida kanala (mm) | 1 - 12 | ||

Debljina materijala (max.)**: | |||

| - Crni čelik (mm) | 25 | 25 | 25 |

| - Nerđajući čelik (mm) | 15 | 25 | 25 |

| - Aluminijum (mm) | 12 | 25 | 25 |

| - Mesing (mm) | 8 | 15 | 18 |

| - Bakar (mm) | 6 | 12 | 12 |

Dimenzije: | |||

| Dužina (mm)*** | 12505 | ||

| Širina (mm) | 2915 | ||

| Visina (mm) | 2532 | ||

* Maksimalna snaga u režimu rotacionog indeksiranja = 3 kW

** Maksimalni iznos debljine zavisi od kvaliteta materijala i radne sredine

*** Mašina + Izmenjivi sto (LST)

Tehnički podaci mogu da variraju zavisno od konfiguracije / opcija

Molimo vas kontaktirajte nas za dodatne detalje i opcije ili svucite našu brošuru

For your safe use

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1