VENTIS-AJe je najveća inovacija u sečenju čelika i predstavlja sledeću generaciju mašina za sečenje Fiber laserom.

Ono što ovu tehnologiju čini zaista revolucionarnom je inovativni sistem oblikovanja laserskog snopa koji omogućava preciznu kontrolu kretanja istog. AMADA jednostruki diodni Fiber laser modul pruža vrlo kvalitetan laserski zrak. VENTIS-AJe (4, 6, 9 kW) će imati slične performanse kao i standardni laseri veće snage, sa mnogo manjom potrebom za snagom i kvalitetom sečenja bez premca.

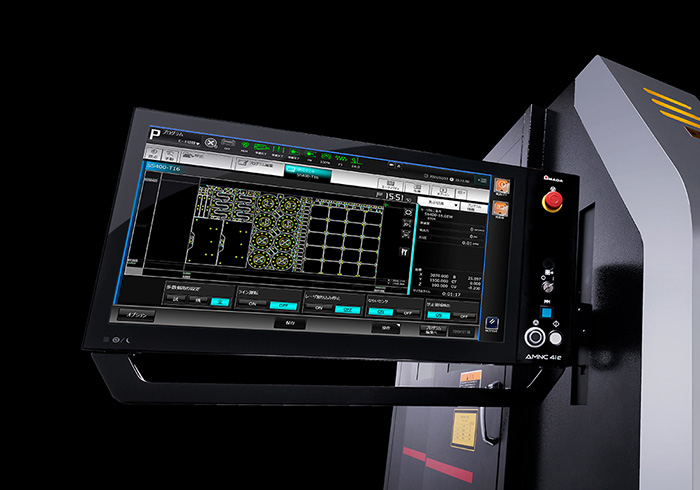

AMNC 4ie

The new AMNC 4ie system is built to provide ease-of-use and increased productivity, with several features such as facial recognition and service tutorial videos assist less experienced operators to achieve increased productivity. Connection to AMADA's IoT sercvice and support systems also helps improve green light on time.

V-MONITOR

Check the production status of multiple machines using the simple V-monitor system. Remote support can also access HD videos for quick issue diagnosis.

COMPRESSED AIR CUTTING

Minimising part cost is a major focus for all manufacturers. AMADA's compressed air cutting capabilities (standard on the VENTIS-AJe) are class leading for speed and thickness.

| VENTIS-3015AJe | |||

|---|---|---|---|

| Snaga lasera (W) | 4000 | 6000 | 9000 |

| Tip mašine | Fiber laser mašina za sečenje | ||

| Radni opseg X x Y (mm) | 3070 x 1550 | ||

| Radni opseg Z-ose (mm) | 100 | ||

| Ponovljivost preciznosti (mm) | ± 0.01 | ||

| Nosivost stola (kg) | 920 | ||

| Pogonski sistem | Spiralni nosač i zupčanik | ||

Debljina materijala (max.)*: | |||

| - Crni čelik (mm) | 25 | 25 | 30** |

| - Nerđajući čelik (mm) | 20 | 25 | 30** |

| - Aluminijum (mm) | 15 | 25 | 25 |

| - Mesing (mm) | 10 | 15 | 18 |

| - Bakar (mm) | 8 | 12 | 12 |

Dimenzije: | |||

| Dužina (mm)*** | 9511 | ||

| Širina (mm) | 2840 | ||

| Visina (mm) | 2236 | ||

| Težina (kg) | 8900 | 9100 | TBC |

| VENTIS-4020AJe | |||

|---|---|---|---|

| Snaga lasera (W) | 4000 | 6000 | 9000 |

| Tip mašine | Fiber laser mašina za sečenje | ||

| Radni opseg X x Y (mm) | 4070 x 2050 | ||

| Radni opseg Z-ose (mm) | 100 | ||

| Ponovljivost preciznosti (mm) | ± 0.01 | ||

| Nosivost stola (kg) | 1570 | ||

| Pogonski sistem | Spiralni nosač i zupčanik | ||

Debljina materijala (max.)*: | |||

| - Crni čelik (mm) | 25 | 25 | 25** |

| - Nerđajući čelik (mm) | 20 | 25 | 25** |

| - Aluminijum (mm) | 15 | 25 | 25 |

| - Mesing (mm) | 10 | 15 | 18 |

| - Bakar (mm) | 8 | 12 | 12 |

Dimenzije: | |||

| Dužina (mm)** | 11482 | ||

| Širina (mm) | 3340 | ||

| Visina (mm) | 2236 | ||

| Težina (kg) | 12400 | 12700 | TBC |

* Maksimalni iznos debljine zavisi od kvaliteta materijala i radne sredine

** Naknadno će biti potvrđeno. Debljina 30 mm za LST 3015 E. 25 mm za LST 4020 E.

*** Mašina + Izmenjivač paleta (LSTe)

Tehnički podaci mogu da variraju zavisno od konfiguracije / opcija

Molimo vas kontaktirajte nas za dodatne detalje i opcije ili svucite našu brošuru

For your safe use

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1