AMADA wishes you a Merry Christmas 2025

We will be closed for the holidays from 24 December 2025 to 1 January 2026. Spare parts will be shipped until 12 noon on 23 December 2025.

More

We will be closed for the holidays from 24 December 2025 to 1 January 2026. Spare parts will be shipped until 12 noon on 23 December 2025.

More

Anlieferung und Inbetriebnahme einer AMADA VALSTER-3015AJ Faserlaser-Anlage bei der Willme Laser–und Stanztechnik GmbH & Co. KG. Wir bedanken uns ganz herzlich bei der Willme Laser– und Stanztechnik GmbH & Co. KG für das entgegengebrachte Vertrauen und wünschen dem gesamten Team viel Erfolg und höchste Produktivität mit der neuen Anlage!

More

Erleben Sie die FLW-ENSISe live in Aktion!

More

Are you still setting up your press brake manually?

More

Be honest—how fast is your fiber laser really? Compete against us live on November 11, 2025 with your time!

More

The new AMADA ORSUS-3015AJe laser cutting machine delivers greater performance, precision, and flexibility in manufacturing.

More

Looking to start laser processing and achieve results immediately? ???? The new AMADA ORSUS-AJe fiber laser makes it possible!

More

The Heun Gruppe relies on state-of-the-art technology in contract manufacturing and has therefore opted for our AMADA FLW-ENSISe! These factors were decisive:

More

For decades, BVS Blechtechnik GmbH has relied on AMADA robot systems – known for their reliability, minimal susceptibility to faults, simple operation and intuitive external programming. Based on this positive experience, BVS once again chose AMADA and invested in the innovative EGB-1303ARse robot cell.

More

Apply to take part in the 38th Precision Sheet Metal Technology Fair – your AMADA sales representative will contact you shortly, assist you with submitting your component and discuss the next steps with you.

More

The ORSUS-3015AJe is AMADA’s solution for companies looking to create a solid foundation for their first step into the world of high speed, precision laser cutting. It creates a perfect starting point for any manufacturer, with available power levels from 3 to 8kW alongside a whole range of advanced technology and features, allowing it to fit into many production environments.

More

Mit der neuen EM-MIIe Serie setzen wir Maßstäbe in Sachen Produktivität, Nachhaltigkeit und Digitalisierung!

More

The new HRB-1003 ATC press brake has arrived - and with it a new benchmark in terms of productivity and efficiency!

More

Bei dem Unternehmen MetallForum Metallbau GmbH ist vor Kurzem eine neue AMADA Maschine eingezogen

More

When every second counts, the FLW-ENSISe shows what real efficiency means. With up to 30 metres per minute ...

More

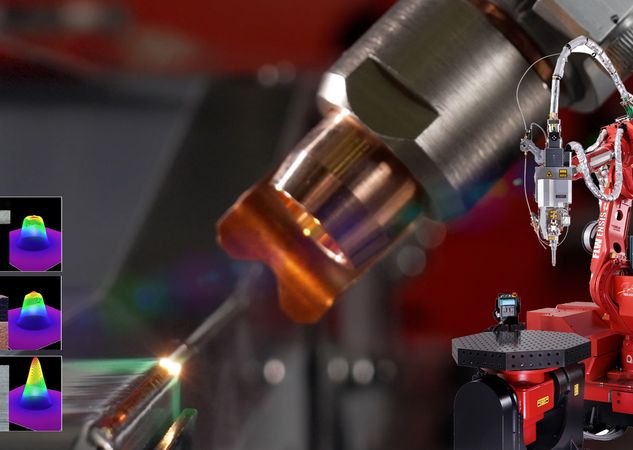

Depending on the requirements, the AMADA FLW-ENSISe operates flexibly with or without welding wire – even within a single component.

More

With WEAVING technology, the laser beam rotates using a lens while the robot itself remains stationary. The basis for this is the powerful...

More

Laser welding often requires customised adjustment of the laser beam depending on the task.

More

Just imagine: All manufacturing processes in your company interlock seamlessly - perfectly coordinated, as if from a single mould. ✅ With AMADA ONE, this vision becomes reality. AMADA ONE combines...

More

We are pleased to announce the extension of our sponsorship agreement with Rahal Letterman Lanigan Racing (RLL). On 25 May 2025, two-time Indy 500 winner Takuma Sato will once again line up in the AMADA design for Rahal Letterman Lanigan Racing with the starting number 75 at the legendary 109th Indianapolis 500 - with the clear aim of taking his third victory in this tradition-steeped race.

More

Our VENTIS-3015AJe 9kW has made it – she has arrived safely at the AMADA branch in Italy! After her exciting journey, she is taking a short break here to process all the impressions. But the break doesn’t last long – the next stop is...

More

It's a magical moment every year when our 30 Japanese cherry trees blossom in spring and transform the AMADA Allee into a sea of delicate pink. The Japanese cherry blossom (sakura) is much more than an impressive natural phenomenon...

More

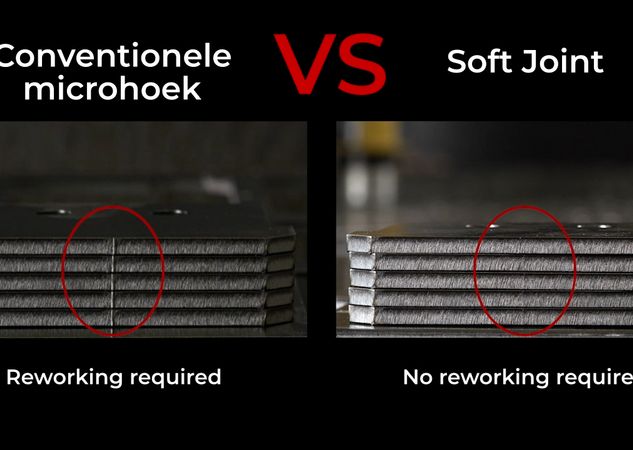

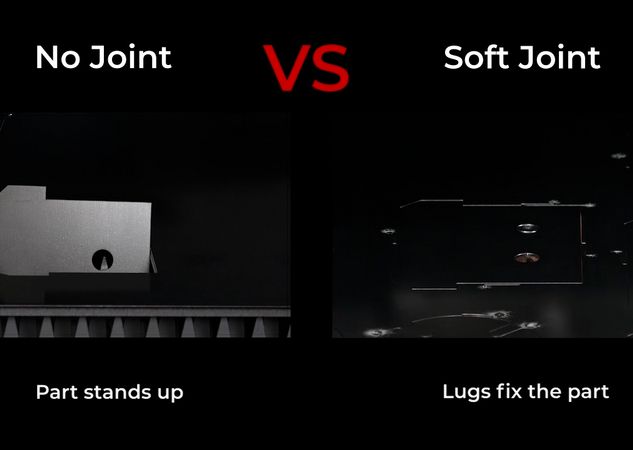

Parts that stand up and the grinding away of micro-corners require additional labour and lead to significantly higher production costs. AMADA Soft Joint technology ensures smooth processes that make these problems a thing of the past.

More

NEW in Show Room Haan: Our smallest welding robot FLW-Le now also enriches our show room in Haan and feels right at home next to its big brother, the FLW-ENSISe. The FLW-Le is perfect for companies that...

More

With the conventional micro corner, the part is firmly connected to the sheet, which means that reworking is almost always necessary and costs valuable time. With the AMADA soft joint process, there is no fixed connection to the sheet metal, so there is no need for reworking and you save valuable time! ????

More

Our machine has arrived! The truck from ‘Schwandner Logistik+Transport’ has safely transported our VENTIS-3015AJe 9 kW from Haan to the exhibition centre in Lyon, France. Using an electric crane from ‘Felix Transports, Manutention, Levage’, she has now been placed in her position on the exhibition stand – ready for the global industry!

More

After a successful in-house exhibition in Haan, our AMADA fibre laser cutting machine VENTIS-3015AJe 9kW is going on a long journey. With the support of ‘Eugen Scalabrin GmbH & Co. KG’, she was safely loaded onto the truck from the demo hall in Haan by crane.

More

If the cutting head collides with the part that is standing up, this can not only stop the process but also cause damage to the system. Our solution: The patented AMADA Soft Joint process!

More

Today, our wide range of press brakes took centre stage. Our visitors were particularly impressed by the HFE3i-4004L, on which we demonstrated the SF-200 bending aids. These support the bending of large and heavy workpieces - with one table up to 200 kg, with both even up to 400 kg! Also in the spotlight...

More

Yesterday at 9 a.m. the doors opened for the first day of our third in-house exhibition this month – and the sun was shining brightly with us! Shortly after the opening, the hall was filled with interested visitors and the first demo parts were successfully folded on our HRB-1303 press brake.

More

Two exciting days of intensive discussions are behind us. ???? At the in-house exhibition ‘It's your SOLUTION’ in Landshut, the focus was on...

More

The in-house exhibition in Landshut started today in bright sunshine! Today and tomorrow, our experts will be presenting customised solutions – from prototyping to mass production – with a focus on top quality and efficiency.

More

AMADA’s BLANK to BEND solution: Integrating both blanking and bending into the same automation system offers significantly increased efficiency by streamlining the production flow, as well as minimising the need for manual handling, peripheral logistics (such as forklifts), and work-in-progress areas.

More

Take your production to a new level with the AMADA BLANK to BEND solution! Thanks to the networking of cutting and punching systems with automatic press brakes, you benefit from constant top performance - around the clock. Want to automate even more? Stay tuned and discover the final automation solution from AMADA soon!

More

Today marked the start of the first in-house exhibition in 2025 - in glorious sunshine! The first of three in-house exhibition days at our subsidiary in Reutlingen has been running at full speed since 9 a.m. this morning.

More

Improve your cutting and bending processes with the automated and efficient loading and unloading systems from AMADA.

More

Do you have problems with your material flow, manual material storage or inventory management in your production?

More

Every year AMADA CO., LTD. creates a unique design in the sign of the zodiac year - and this year it's the snake!

More