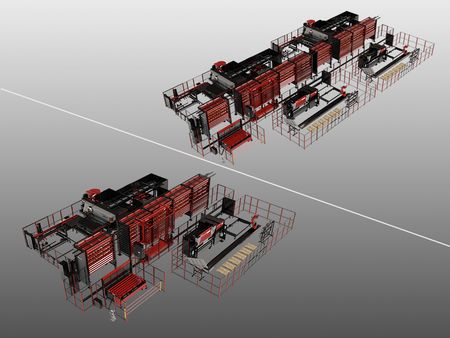

AMADA’s new BLANK to BEND solution is the perfect addition to your new or existing blanking line connected to a Compact Storage (CS) system. Integrating both blanking and bending into the same automation system offers significantly increased efficiency by streamlining the production flow, minimising the need for manual handling, peripheral logistics such as forklifts, and buffer areas. The fully automated system provides outstanding performance 24/7 - for your benefit.

HIGH PRODUCTIVITY

SUSTAINABILITY

SCALABILITY