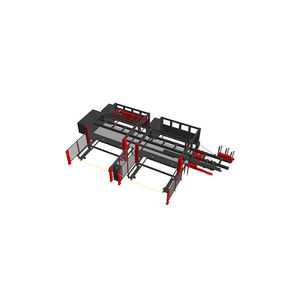

The LC-2515C1 AJe combination machine brings together the high performance of AMADA’s electric punching system with the low energy consumption of AMADA’s fibre laser cutting.

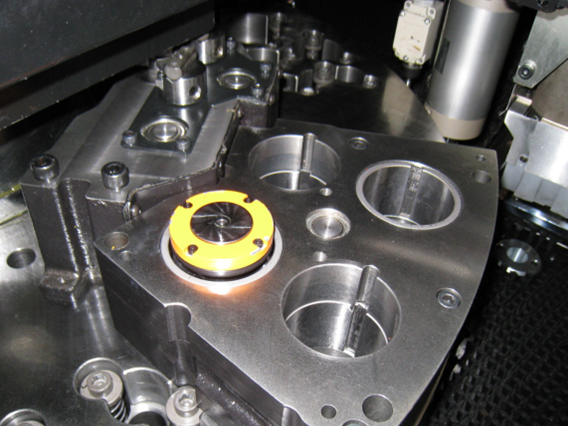

The 46 station turret with 4 tapping units offers superb versatility, with no setup errors thanks to the AMADA ID Tooling System (AITS) that can precisely monitor the position of the punch and any need for tool maintenance entirely automatically.

ALL ELECTRIC PUNCHING

The LC-C1 AJe uses a single AC servo motor to generate 20 tons of punching force, providing possibilities to produce a wide range of punched and formed parts. This system can use up to 70% less electricity compared to typical hydraulic systems.

MULTI-PURPOSE TURRET:

The LC-C1 AJe is equipped with a multi-purpose turret that also includes a dedicated tapping unit, for M2.5 to M8 taps.

ERROR PREVENTION:

With the AMADA ID Tooling System (ITS), setup errors are avoided and damage prevented.

| LC-2515C1AJe | |

|---|---|

| Press capacity (kN) | 200 |

| Laser power (W) | 3000 |

| Machine frame | Bridge frame |

| Punching accuracy (mm) | ± 0.1 |

| Table loading weight (kg) | 220 |

Simultaneous axis speed: | |

| Punching X/Y (m/min) | 128 |

| Laser X/Y (m/min) | 113 |

Dimensions: | |

| Length (mm) | 6420 |

| Width (mm) | 6927 |

| Height (mm) | 2377 |

| Weight (kg) | 20000 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1