The VENTIS-AJe is the biggest innovation in sheet metal cutting and introduces the next generation of fibre laser processing machines.

What makes this technology truly revolutionary is the innovative beam control system that allows for precise control of the laser beam motion. Utilizing AMADA’s high power, single diode module fibre laser engines, the VENTIS-AJe is available as 4, 6 and 9 kW. These engines provide a very high quality laser beam, allowing the VENTIS-AJe to have similar performance to higher power standard lasers, with much less power requirements and an unrivalled cutting quality.

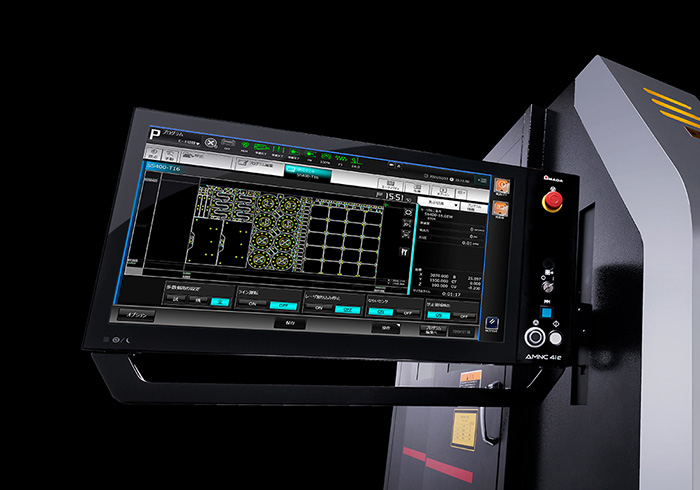

AMNC 4ie

The new AMNC 4ie system is built to provide ease-of-use and increased productivity, with several features such as facial recognition and service tutorial videos assist less experienced operators to achieve increased productivity. Connection to AMADA's IoT sercvice and support systems also helps improve green light on time.

V-MONITOR

Check the production status of multiple machines using the simple V-monitor system. Remote support can also access HD videos for quick issue diagnosis.

COMPRESSED AIR CUTTING

Minimising part cost is a major focus for all manufacturers. AMADA's compressed air cutting capabilities (standard on the VENTIS-AJe) are class leading for speed and thickness.

| VENTIS-3015AJe | |||

|---|---|---|---|

| Laser power (W) | 4000 | 6000 | 9000 |

| Machine type | Fibre laser cutting machine | ||

| Working range X x Y (mm) | 3070 x 1550 | ||

| Working range Z-axis (mm) | 100 | ||

| Repeatable positioning accuracy (mm) | ± 0.01 | ||

| Table loading weight (kg) | 920 | ||

| Drive system | Helical rack and pinion | ||

Material thickness (max.)*: | |||

| - Mild steel (mm) | 25 | 25 | 30** |

| - Stainless steel (mm) | 20 | 25 | 30** |

| - Aluminium (mm) | 15 | 25 | 25 |

| - Brass (mm) | 10 | 15 | 18 |

| - Copper (mm) | 8 | 12 | 12 |

Dimensions: | |||

| Length (mm)*** | 9511 | ||

| Width (mm) | 2840 | ||

| Height (mm) | 2236 | ||

| Weight (kg) | 8900 | 9100 | TBC |

| VENTIS-4020AJe | |||

|---|---|---|---|

| Laser power (W) | 4000 | 6000 | 9000 |

| Machine type | Fibre laser cutting machine | ||

| Working range X x Y (mm) | 4070 x 2050 | ||

| Working range Z-axis (mm) | 100 | ||

| Repeatable positioning accuracy (mm) | ± 0.01 | ||

| Table loading weight (kg) | 1570 | ||

| Drive system | Helical rack and pinion | ||

Material thickness (max.)*: | |||

| - Mild steel (mm) | 25 | 25 | 25** |

| - Stainless steel (mm) | 20 | 25 | 25** |

| - Aluminium (mm) | 15 | 25 | 25 |

| - Brass (mm) | 10 | 15 | 18 |

| - Copper (mm) | 8 | 12 | 12 |

Dimensions: | |||

| Length (mm)*** | 11482 | ||

| Width (mm) | 3340 | ||

| Height (mm) | 2236 | ||

| Weight (kg) | 12400 | 12700 | TBC |

* Maximum thickness value depends on material quality and environmental conditions

** To be confirmed. 30mm thickness for LST 3015 E. 25mm for LST 4020 E.

*** Machine + shuttle table (LST E)

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1