Foundation For Success

In modern laser cutting, productivity and quality depend not only on available power, but on process continuity: fewer interruptions, fewer variables, and more stable control, even when batch sizes change frequently. ORSUS-AJe fits precisely into this context. It is a solution designed to deliver operational reliability and ease of use, supporting companies that want to grow in laser processing with a solid, intuitive platform oriented toward automation.

INTEGRATED AUTOMATION AND REDUCED OPERATOR INTERVENTION

One of the most significant aspects of ORSUS-AJe is its ability to keep the process stable while reducing repetitive tasks that, in daily operations, tend to slow down production. The automatic nozzle changer with 8 stations goes beyond simple replacement: it also includes cleaning and calibration of the cutting head, helping to minimize downtime and streamline operations.

This is complemented by control systems designed to preserve continuity and quality over time. The i-Optics Sensor monitors the condition of the protective lens glass in real time and signals the most appropriate moment for maintenance, reducing the risk of unplanned stoppages. In parallel, i-Process Monitoring continuously analyzes cutting and piercing quality and automatically intervenes to limit defects and ensure consistent results.

PRODUCTIVITY AND MATERIAL OPTIMIZATION

With cutting power of up to 8 kW, ORSUS-AJe enables high-speed processing while maintaining excellent precision, offering a well-balanced solution for everyday production needs. Efficiency, however, is not expressed solely in cutting performance, but also in the ability to optimize sheet metal usage.

In this regard, WACS II (Water Assisted Cutting System) improves edge quality and allows parts to be positioned closer together, reducing scrap and increasing material efficiency. To safeguard operational continuity, the anti-collision protection device allows the cutting head to retract in the event of impacts, preventing damage and enabling rapid resumption of production.

ADVANCED INTERFACE FOR INTUITIVE CONTROL

Achieving continuity and quality also requires simple interaction that reduces errors and makes program management immediate. ORSUS-AJe integrates the AMNC 4ie numerical control, featuring a 21.5” HD touchscreen designed to provide a clear and accessible operating experience. The easy-edit function allows operators to modify programs directly at the machine in a quick and intuitive way, without complicating their workflow.

This setup is completed by support tools and guided modes dedicated also to maintenance, helping to make operation safer and to simplify daily activities, especially in environments where operators have different levels of experience.

OFFLINE PROGRAMMING AND PROCESS CONTINUITY

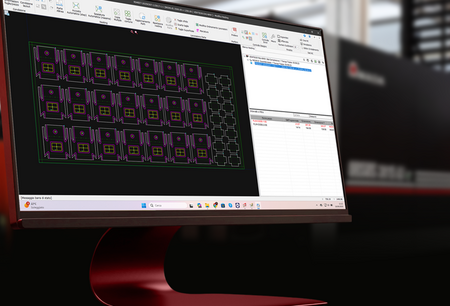

In many companies, true efficiency emerges when the technical office and production work in continuity, without redundant steps or constant on-machine adjustments. For this reason, ORSUS-AJe is supplied with VPSS 4ie, AMADA’s offline programming software, which allows programs to be prepared quickly and in full alignment with the machine environment.

The integration between VPSS 4ie and AMNC 4ie ensures smoother information transfer, reduces setup times, and helps manage variable production more effectively. The result is a more stable and predictable workflow, where digital technology provides tangible support to productivity.