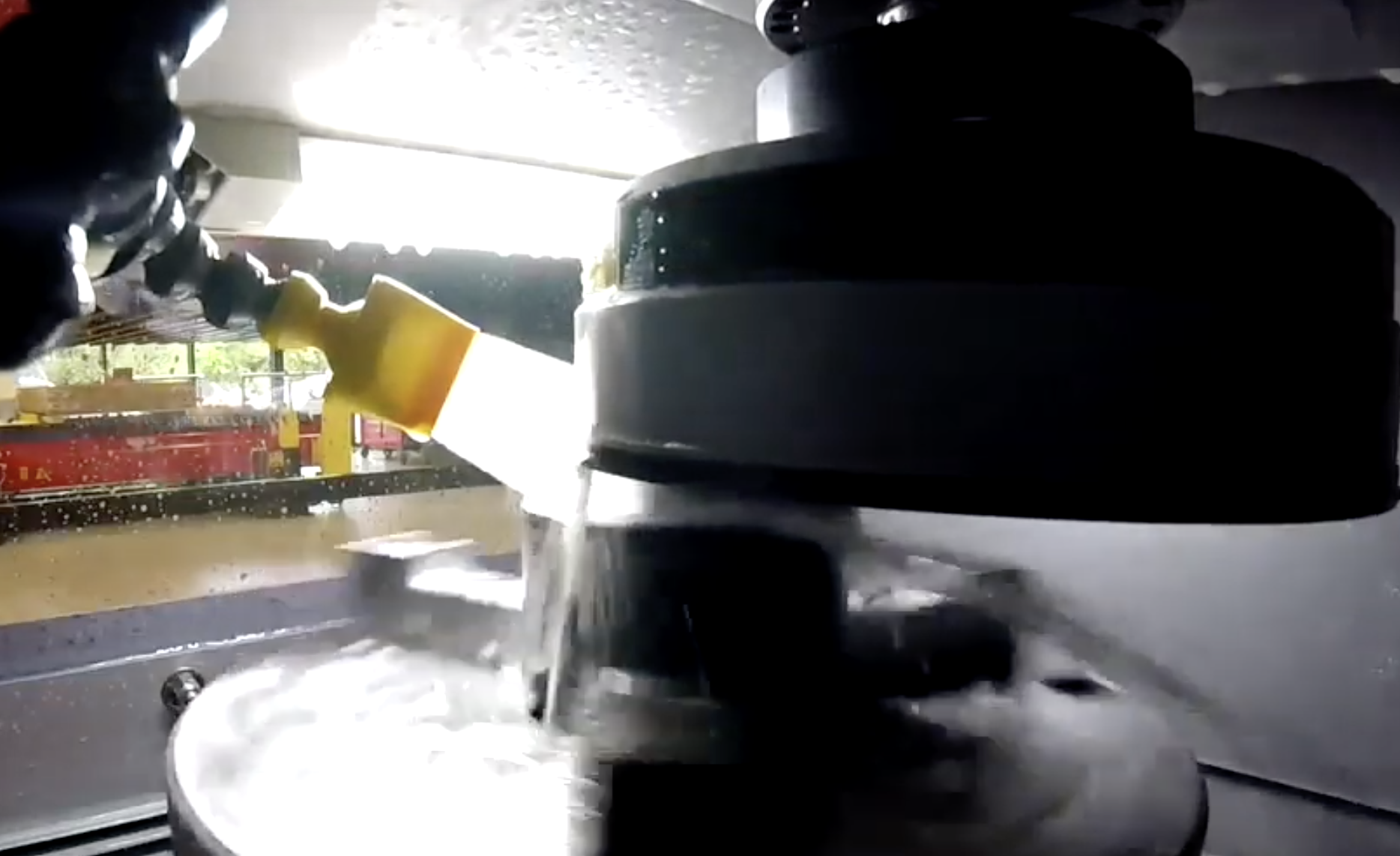

AMADA's ID tooling changes the way you monitor and manage your turret tooling inventory. ID-TOGU digital management provides optimal grinding by taking grinding values from AITS server automatically. Easy and simple to operate. No operator experience is required.

USER-FRIENDLY NUMERICAL CONTROL:

Touchscreen numerical control ensures simple, user-friendly machine programming.

CONNECTION TO THE COMPANY NETWORK:

The ID-TOGU can be connected to the company network and can exchange data with AMADA's AITS server where tool information is stored.

MINIMISING THERMAL STRESS:

Unlike traditional grinding machines, TOGU can minimise the amount of material removed during grinding, preventing the tool from overheating and extending its life.

| ID-TOGU | |

|---|---|

| Tool diameter (min.) | Ø 1.51 |

| Tool diameter (max.) | Ø 160 |

| Vertical traverse (mm) | 240 |

| Air supply | 6 bar / 600 l/min |

Grinding speed: | |

| Stations A / B / C (mm/min) | 0.06 |

| Stations D / E (mm/min) | 0.03 |

Dimensions: | |

| Length (mm) | 850 |

| Width (mm) | 1070 |

| Height (mm) | 1930 |

| Weight (kg) | 700 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.