The ORSUS-3015AJe is AMADA’s solution for companies looking to create a solid foundation for their first step into the world of high speed, precision laser cutting. It creates a perfect starting point for any manufacturer, with available power levels from 3 to 8kW and a whole range of advanced technology and features, allowing it to fit into many production environments. The ORSUS-3015AJe comes fully equipped with a large number of features designed to improve cutting quality, reliability and ease-of-use.

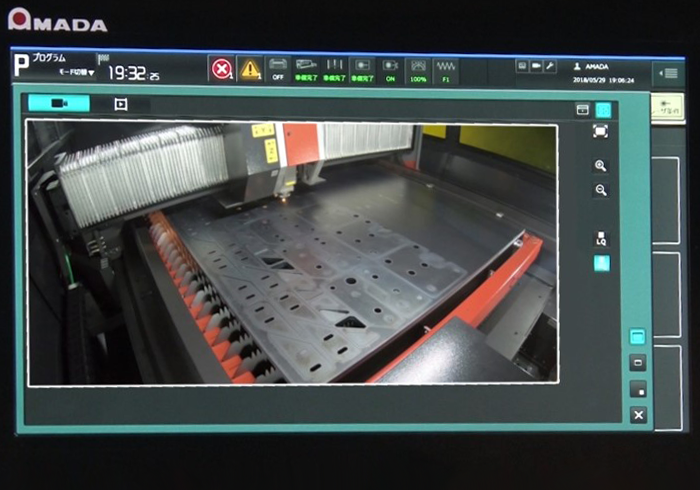

V-MONITOR:

The video from this camera-based system can be viewed on the machine control as well as being available when remotely logging in, allowing both customers and AMADA engineers to understand the machine status. High resolution videos are also automatically recorded in the event of an issue, allowing rapid diagnosis and action to get the machine back into production.

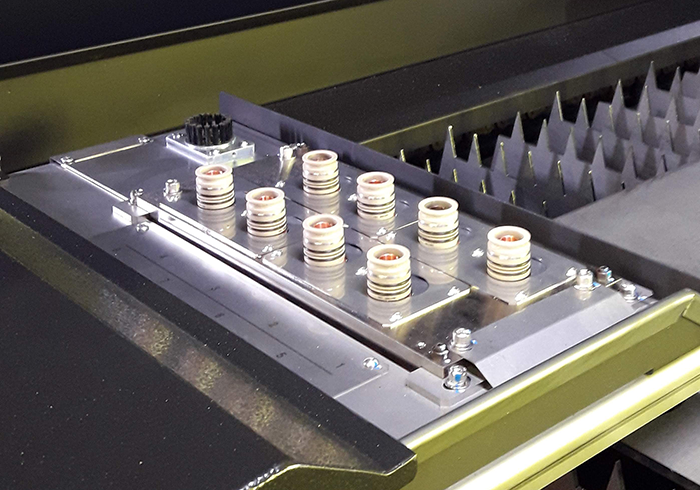

NOZZLE CHANGER:

The 6kW and 8kW ORSUS lasers are equipped with an 8-station nozzle changer, allowing quick changeover without operator intervention. The nozzle is cleaned and the cutting head calibration is also carried out automatically.

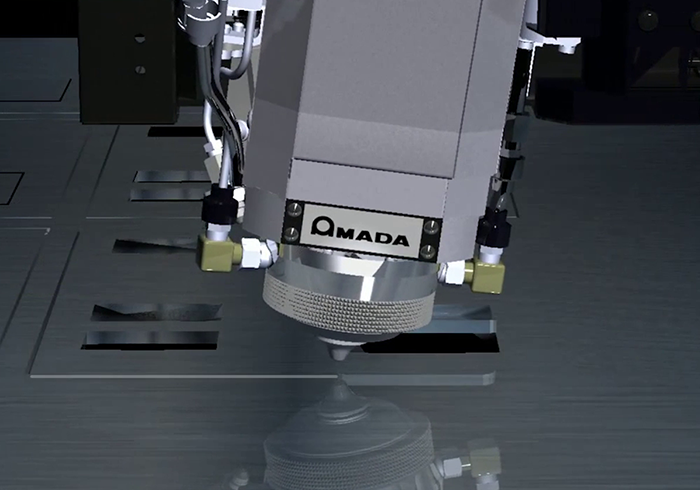

CUTTING HEAD COLLISION DETECTION:

To protect the cutting head and minimise production interruptions, every ORSUS is fitted with a collision detection system which stops the machine and retracts the cutting head. The operator then simply needs to check the situation and restart the cutting.

| ORSUS-3015AJe | |||

|---|---|---|---|

| Laser power (W) | 3000 | 6000 | 8000 |

| Machine type | Fibre laser cutting machine | ||

| Working range X x Y (mm) | 3070 x 1550 | ||

| Working range Z-axis (mm) | 100 | ||

| Repeatable positioning accuracy (mm) | ± 0.01 | ||

| Table loading weight (kg) | 920 | ||

| Drive system | AC Servo drives | ||

Material thickness (max.)*: | |||

| - Mild steel (mm) | 12 | 22 | 25 |

| - Stainless steel (mm) | 15 | 25 | 25 |

| - Aluminium (mm) | 12 | 25 | 25 |

| - Brass (mm) | 8 | 15 | 15 |

| - Copper (mm) | 6 | 10 | 12 |

Dimensions: | |||

| Length - Machine + LST E (mm) | 9505 | ||

| Width (mm) | 2840 | ||

| Height (mm) | 2000 | ||

| Weight (kg) | 8943 | 8993 | 8993 |

* Maximum thickness value depends on material quality and environmental conditions

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1