L-III

More

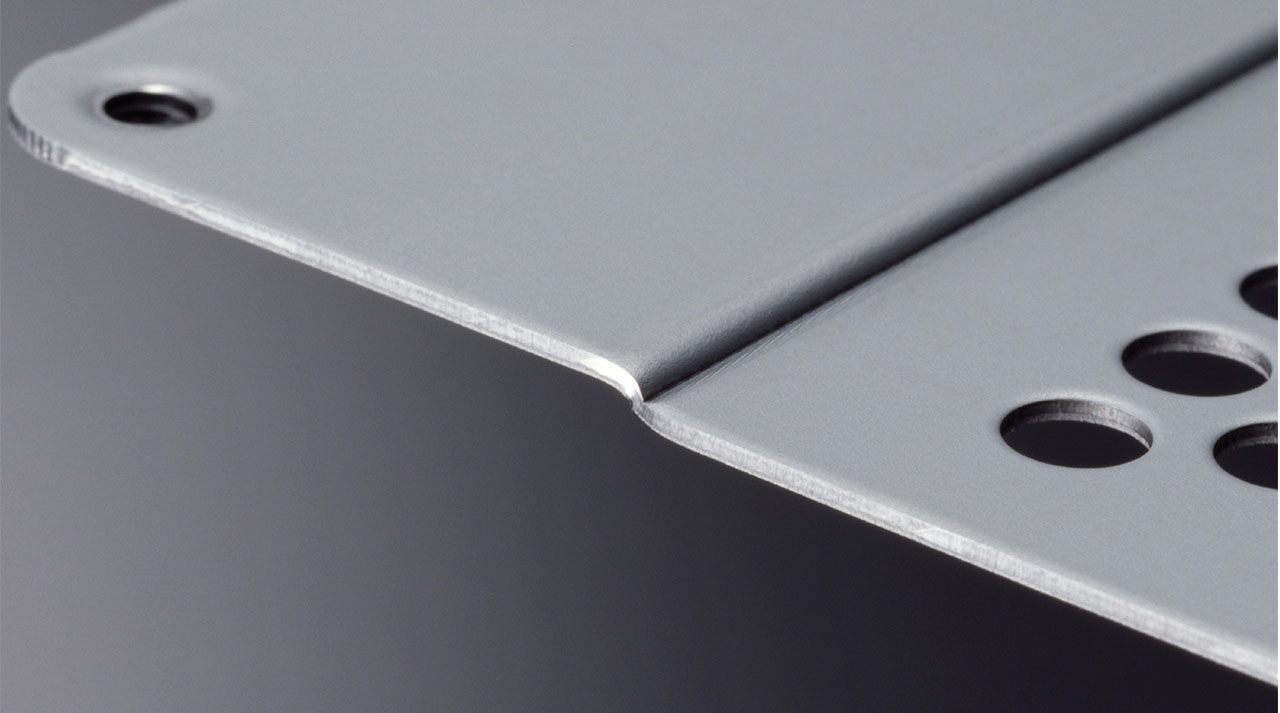

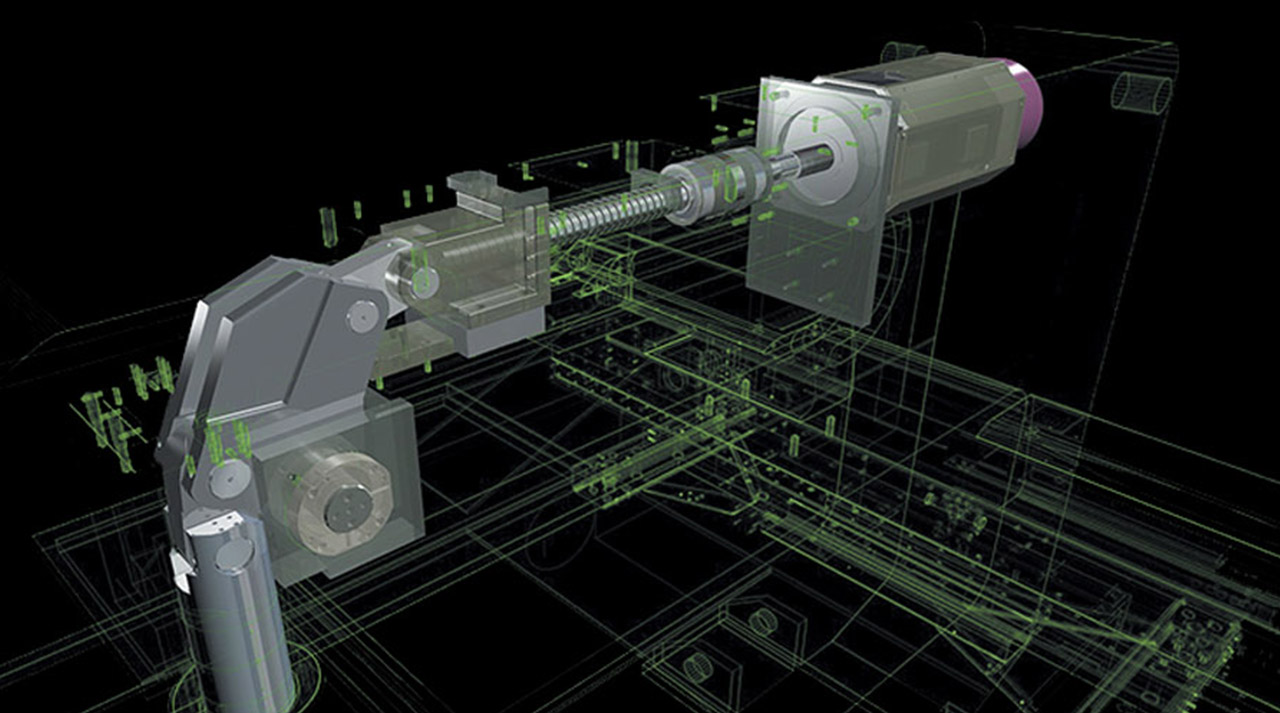

AMADA has installed over 30.000 turret punch machines throughout the world. The AE-NT range has been designed based on our proven track record in the industry and combines an extremely sturdy bridge structure with a servo electric drive punching system, a high-capacity turret and minimal footprint. These features ensure stable, high-speed and high-quality operations.

PRECISION AND RELIABILITY:

The electric servomotor delivers a punching force of 20 tons, with a maximum punching hit rate of 900 strokes/minute.

USER FRIENDLY:

AMNC 3i control is easy and user-friendly. Punching tool setup is quick and ensures minimum downtime, thus maximising productivity.

LOW OPERATING COSTS:

Electric consumption is below 1 kW on standby and 5 kW at maximum power. The total absence of a hydraulic unit and oil ensures low operating costs and low environmental impact.

| AE-255NT | AE-2510NT | AE-2610NT | |

|---|---|---|---|

| Press capacity (kN) | 200 | 200 | 200 |

| Positioning accuracy (mm) | ± 0.1 | ± 0.1 | ± 0.1 |

| Number of stations | 45 | 45 | 45 |

| Machine frame | Bridge frame | Bridge frame | Bridge frame |

| Axis travel distance (mm) | 1270 x 1270 | 2500 x 1270 | 2500 x 1525 |

Dimensions: | |||

| Length (mm) | 4100 | 4155 | 4998 |

| Width (mm) | 2560 | 5120 | 5120 |

| Height (mm) | 2115 | 2115 | 2265 |

| Weight (kg) | 12000 | 12500 | 13800 |

All machines are available with brush table or high density brush table

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.