It is crucial that the flow of blanks, the starting point for the entire manufacturing process, is managed with utmost quality and speed. These two criteria are entrenched in the design and manufacture of AMADA’s GS-II and GX-II sheet metal shears.

The rigidity of the frame, as well as the drive and adjustment solutions, ensure an exceptional degree of reliability and safety of use.

Beyond the technical considerations, these machines were developed with an improvement in working conditions, safety and ergonomics features in mind.

EASY CLEARANCE ADJUSTMENT:

You can easily set the gap between the blades and the cutting angle by using levers on the GS-II model. This is automatic on the GX-II model based on the material thickness you enter on the keypad.

EASY PROGRAMMING:

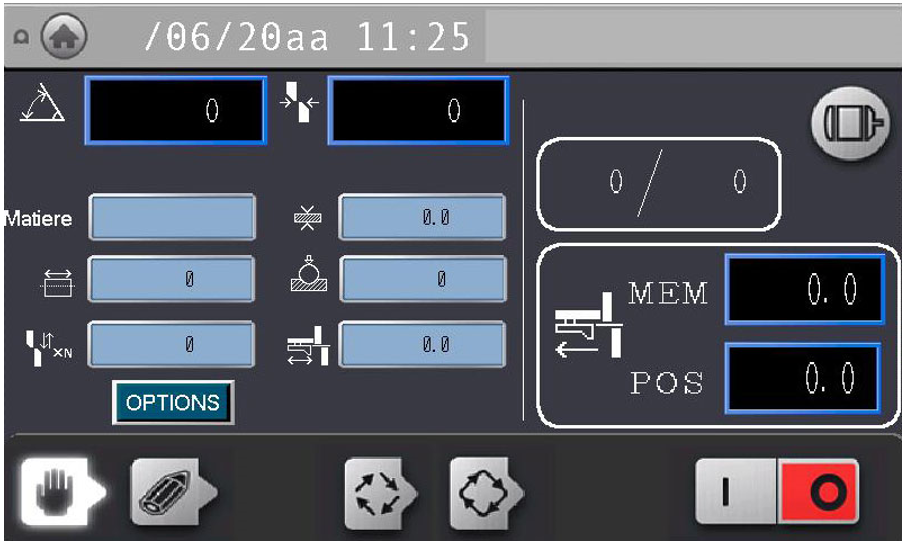

The AMADA keypad was designed with the user in mind.

Equipped with a touchscreen, it automatically manages all the cutting parameters. It has a 50 program memory. The keypad can be pivoted up to 90° so the operator can see the program sequence.

ERGONOMIC FRONT BENCH:

Designed to help mount the numerous optional accessories such as front supports, front brackets with or without micrometric stop.

There are two types of workbench:

- Smooth bench as standard on the GS-II

- Table supports with roller bearings as standard on the GX-II (optional on the GS-II)

| GS II-630 | GS II-840 | GS II-1230 | |

|---|---|---|---|

| Cutting force (kN) | 197 | 271 | 361 |

| Cutting length (mm) | 3050 | 4050 | 3050 |

| Stroke (mm) | 160 | 190 | 190 |

| Maximum speed (cuts/min)* | 33 | 29 | 29 |

Material thickness (max.): | |||

| Mild steel (mm) | 6.35 | 8 | 12 |

| Stainless steel (mm) | 4 | 6 | 8 |

| Aluminium (mm) | 8 | 10 | 14 |

Dimensions: | |||

| Length (mm) | 3790 | 4810 | 3850 |

| Width (mm) | 2250 | 2510 | 2390 |

| Height (mm) | 1866 | 2040 | 2040 |

| Weight (kg) | 6150 | 11530 | 7510 |

| GX II-630 | GX II-840 | GX II-1230 | |

|---|---|---|---|

| Cutting force (kN) | 197 | 271 | 361 |

| Cutting length (mm) | 3050 | 4050 | 3050 |

| Stroke (mm) | 160 | 190 | 190 |

| Maximum speed (cuts/min)* | 33 | 29 | 29 |

Material thickness (max.): | |||

| Mild steel (mm) | 6.35 | 8 | 12 |

| Stainless steel (mm) | 4 | 6 | 8 |

| Aluminium (mm) | 8 | 10 | 14 |

Dimensions: | |||

| Length (mm) | 3790 | 4810 | 3850 |

| Width (mm) | 2250 | 2510 | 2390 |

| Height (mm) | 1866 | 2040 | 2040 |

| Weight (kg) | 6150 | 11530 | 7510 |

* cutting a length of 100 mm

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.