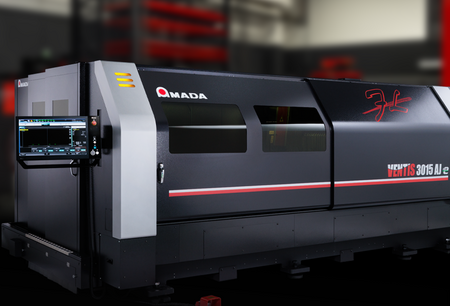

Designed to integrate power, precision, and maximum energy efficiency, this model represents a strategic solution to modern sheet metal processing challenges, fitting seamlessly into digitalized production processes

ADVANCED EFFICIENCY WITH LBC TECHNOLOGY

Locus Beam Control (LBC), the core of the VENTIS-AJe system, is the technology that enables dynamic and precise laser beam control via galvanometric mirrors. With its 9 kW power, the system delivers results comparable to higher power machines, yet with significantly reduced energy consumption. This solution ensures flawless cuts on materials such as stainless steel, carbon steel, and aluminum, even at high thicknesses, guaranteeing top-quality finishes with no dross and outstanding operational efficiency.

OPERATING MODES FOR EVERY NEED

VENTIS-AJe stands out for its operational versatility, ensured by multiple dedicated modes tailored to different cutting requirements:

Thanks to these features, VENTIS-AJe provides flexible and fast responses to all production needs.

FULL INTEGRATION FOR SMART MANUFACTURING

Digital readiness is one of the key strengths of VENTIS-AJe. The system is fully compatible with AMADA’s VPSS 4ie and LIVLOTS software suites—cutting-edge digital platforms that allow you to monitor, manage, and simulate every step of the production process: from design to cutting, bending, and welding.

The user interface has been further enhanced through the new AMNC 4ie CNC control, developed to ensure maximum ease of use and a significant productivity boost.

Advanced features such as facial recognition, built-in video tutorials for operator support, dedicated tools for less experienced users, and direct connection to AMADA’s IoT support systems help optimize delivery times and ensure even more efficient and accurate production management.

VENTIS-AJe 9 kW is not just a laser cutting machine—it is an integrated and intelligent solution, essential to face the challenges of the industrial future. Technological innovation is combined with the strategic vision of the digital factory, making this system an indispensable tool for companies aiming to enhance the quality, speed, and efficiency of their manufacturing processes.