ASR 3015 PR

More

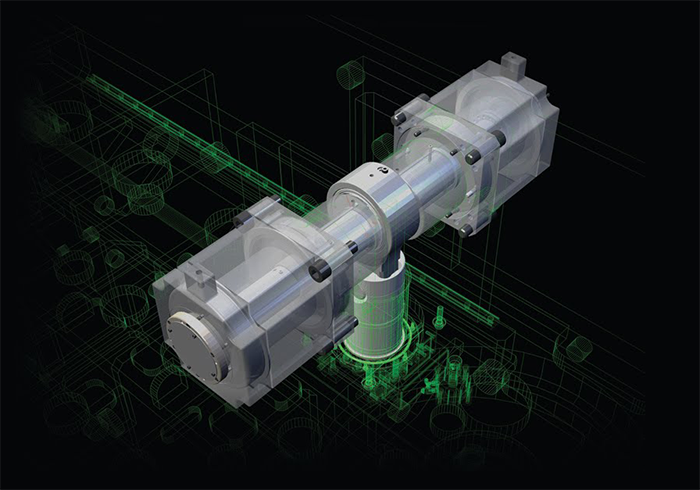

The ACIES-AJe is the most advanced technology for punch/laser combination machines. Equipped with a 3 kW AMADA fibre engine, a 30 ton electric punching system and an automatic tool changer that holds up to 300 punches and 600 dies, the ACIES-AJe can provide the utmost productivity and flexibility.

FULLY ELECTRIC PUNCHING

Utilising AMADA's proven dual servo motor punching system, the ACIES-AJe provides 30 tons of punching force and high hit rates, whilst significantly reducing electrical consumption.

COMPRESSED AIR CUTTING

With cutting speeds generally the same as nitrogen cutting, but at a fraction of the part cost, compressed air cutting is provided as standard on the ACIES-AJe.

ID TOOLING

Extending tool life and drastically reducing setup errors, ID Tooling scans every tool when it is loaded to confirm all the relevant information before, during and after processing.

| ACIES-2515BAJe | ACIES-2515TAJe | |

|---|---|---|

| Press capacity (kN) | 300 | |

| Laser power (W) | 3000 | |

| Machine frame | Bridge frame | |

| Punching accuracy (mm) | ± 0.1 | |

| Table loading weight (kg) | 220 | |

Simultaneous axis speed: | ||

| Punching X/Y (m/min) | 128 | |

| Laser X/Y (m/min) | 141 | |

Dimensions: | ||

| Length (mm) | 6242 | 7090 |

| Width (mm) | 6927 | 6927 |

| Height (mm) | 2524 | 2666 |

| Weight (kg) | 25700 | 29300 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1