ASR 3015 PR

More

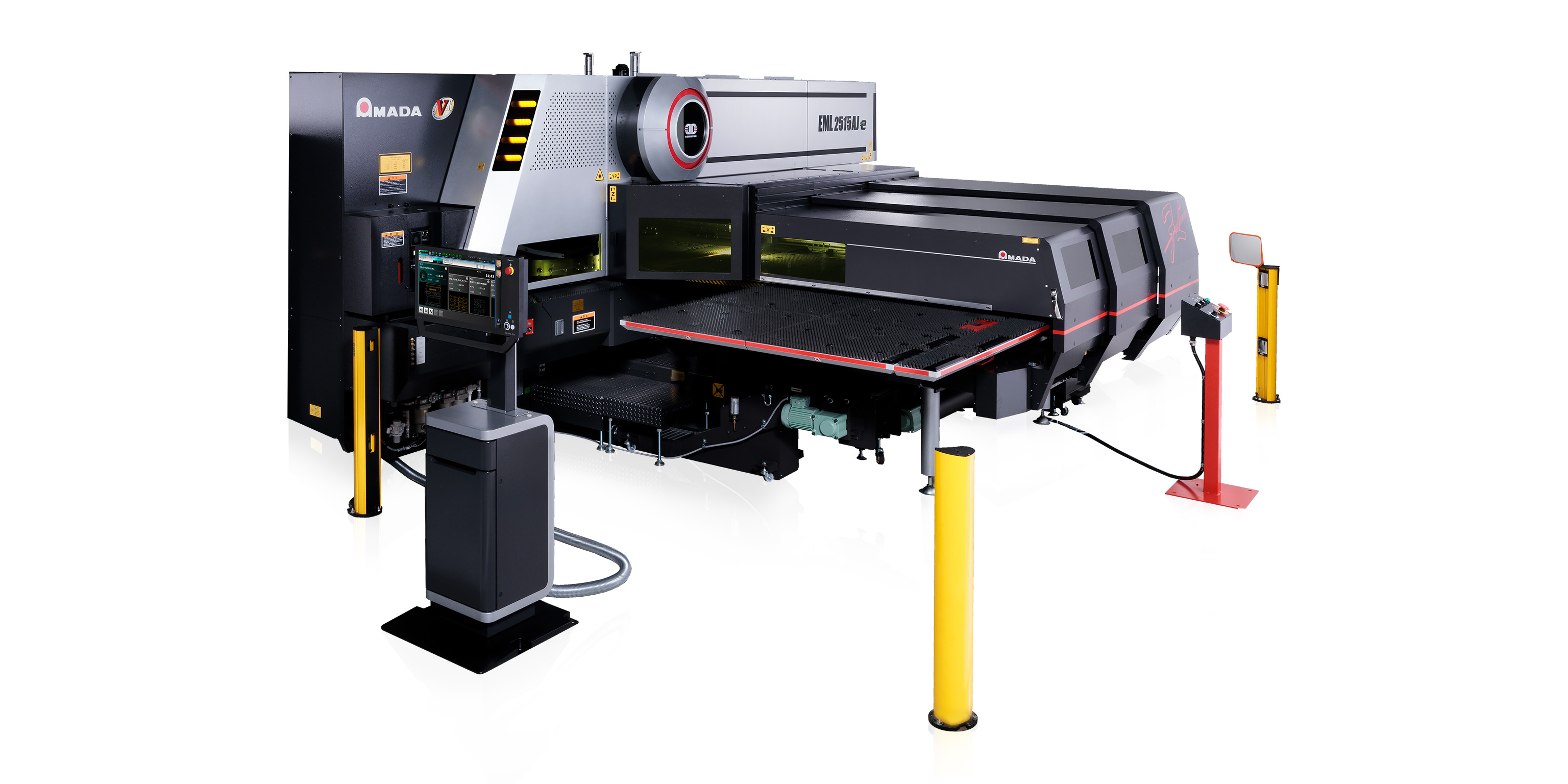

The EML-AJe combination machine uniquely and perfectly brings together AMADA’s patented dual servo motor punching technology and a quick, integrated hybrid drive AMADA fibre optic laser. Designed to minimise manual operations, it is ideal for full-range processing.

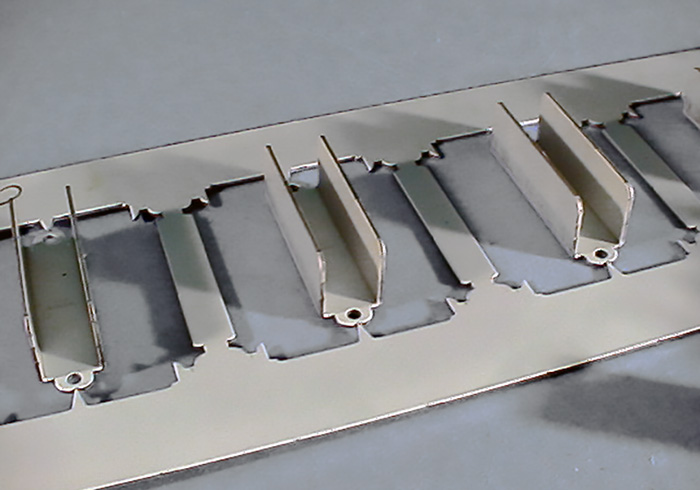

PUNCH & FORM (P&F) SYSTEM

To compliment the already high capabilities of the EML-AJe machine, the P&F system is also included as standard. This consists of a 16 ton forming system which activates the die to allow the processing of forms up to 22mm high.

COMPRESSED AIR CUTTING

A wide range of materials and thicknesses can be processed with compressed air on the EML-AJe as standard. This drastically reduces the assist gas costs and leads to higher profitability. Cutting speeds are generally the same as with nitrogen.

ID TOOLING

Punches and dies are immediately identified and tracked for number of hits, sharpening amount, and remaining life, helping to minimize set up mistakes. The tool angle and appropriate die selection are also confirmed upon installation.

| EML-2515AJe | EMLZ-2515AJPe | |

|---|---|---|

| Press capacity (kN) | 300 | |

| Laser power (W) | 3000 | |

| Machine frame | Bridge frame | |

| Punching accuracy (mm) | ± 0.1 | |

| Number of stations | 44 | |

| Tool turret type | Z-Turret | |

| Table loading weight (kg) | 220 | |

| Table drive | AC Servo drives | |

Simultaneous axis speed: | ||

| Punching X/Y (m/min) | 128 | |

| Laser X/Y (m/min) | 141 | |

Dimensions: | ||

| Length (mm) | 5689 | 6808 |

| Width (mm) | 6927 | 6927 |

| Height (mm) | 2525 | 3010 |

| Weight (kg) | 24000 | 27500 |

PDC (Automatic Punch / Die Changer)

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1