AS-III

More

The EM-ZRe range is equipped with an unrivalled dual servo motor drive system and AMADA’s unique ZR turret - a highly innovative feature for turret punching machines. With an automatic tool changing system and digital tool management (AMADA ID Tooling System-AITS), the EM-ZRe range is ideal for the continuous manufacturing of small, variable lots.

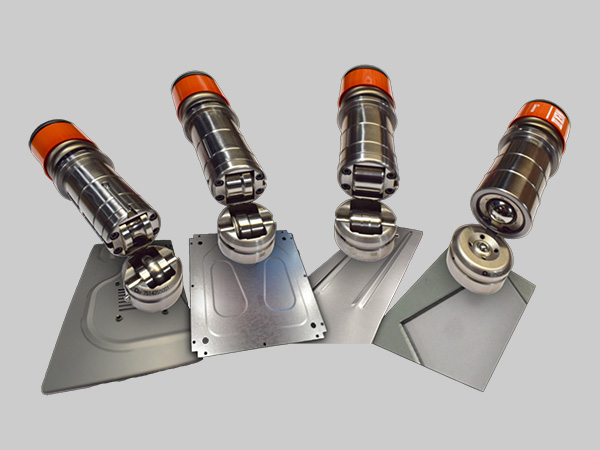

ID TOOLING

Eliminating costly tool set up errors and helping to increase tool life are two of the main factors associated with the ID Tooling system. Every tool is scanned before and after processing, with maintenance messages displayed to the operator when grinding is required.

AMADA RAPID FORMING TOOL COMPATIBILITY

The EM-ZRe is supplied with the ability to support AMADA Rapid Forming Tools (ARFT) for continuous, quick forming of more complex profiles such as offsets, beading and chamfering.

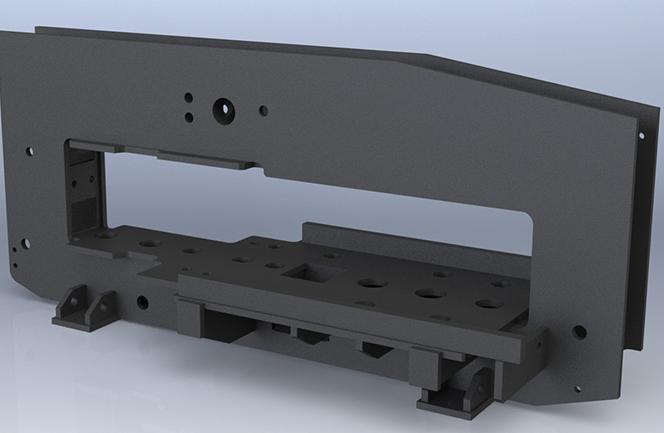

THE ORIGINAL FRAME

AMADA's original bridge frame design ensures that any deflection due to punching forces does not affect the alignment between punch and die as the tool is always in a central position, potentially extending tool life.

| EM-3510 ZRBe | EM-3510 ZRTe | EM-3612 ZRBe | EM-3612 ZRTe | ||

|---|---|---|---|---|---|

| Buffer Turret | Tool Storage Unit | Buffer Turret | Tool Storage Unit | ||

| Turret - Number of stations | 32 ZR ( 4 Auto Index stations) | ||||

| Press capacity (kN) | 300 | ||||

| Drive system | AC servo, direct twin drive | ||||

| Punching accuracy (mm) | ± 0.1 | ||||

| Axis travel distance (mm) | 2500 x 1275 | 3050 x 1525 | |||

| Machine frame | Bridge frame | ||||

Dimensions | |||||

| Length (mm) | 6157 | 7005 | 6582 | 7415 | |

| Width (mm) | 5120 | 5120 | 6220 | 6220 | |

| Height (mm) | 2367 | 2666 | 2367 | 2666 | |

| Weight (kg) | 20000 | 23500 | 21500 | 25000 | |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.