When it comes to sheet metal processing, every phase of the production cycle is closely interconnected. Among all the steps, bending plays a crucial role that significantly impacts the final quality of welding. A precisely and accurately executed bend ensures perfect surface contact and drastically reduces the need for corrective interventions during the welding phase. For this reason, AMADA has developed an advanced technological solution: the EGB-ATCe electric press brake

EGB-ATCe: PRECISION AND RELIABILITY FOR ELECTRIC BENDING

The EGB-ATCe servo-electric press brake was designed to deliver impeccable results in terms of precision, speed, and reliability. Equipped with an asymmetric dynamic compensation system and the innovative BI-S II automatic angle measurement device, the EGB-ATCe ensures consistent bending quality across the entire surface of the workpiece. This uniformity is key to obtaining strong, defect-free welded joints and greatly facilitates the operator's work during the subsequent production phases.

SMART AUTOMATION THAT SIMPLIFIES EVERY OPERATION

The precision offered by the EGB-ATCe is further enhanced by its user-friendliness and high level of integrated automation. The automatic tool changer (ATC), now 30% more capable, allows for rapid machine setup, eliminating downtime and significantly increasing overall productivity. Thanks to smart features such as the HMI tablet, dual display with augmented reality, and integrated voice control, managing the press brake becomes highly intuitive—making it possible even for less experienced operators to achieve perfect results from the very first use.

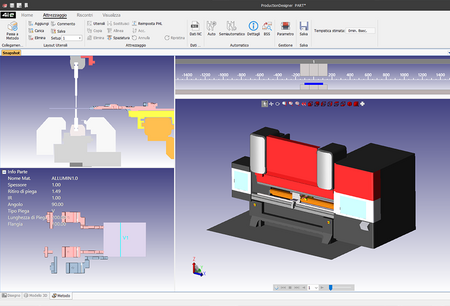

ADVANCED SOFTWARE FOR SIMPLE AND ACCURATE PROGRAMMING

Bending quality begins well before the physical process itself: during the programming phase, all the necessary parameters are defined to ensure perfect integration between bending and welding. This is where VPSS 4ie Bend comes into play—AMADA’s software that uses artificial intelligence to automatically program press brakes. With VPSS 4ie Bend, it is possible to accurately define optimal bending sequences and automatically calculate the most efficient tool setups. The result is a drastic reduction in errors, less material waste, and significantly shorter processing times.

Using EGB-ATCe in combination with VPSS 4ie Bend creates a seamless synergy between bending and welding, ensuring efficient and waste-free production processes. Thanks to this integration, companies can produce stronger welded joints, improve the aesthetic quality of their products, and drastically reduce the need for rework.

Learn more on the dedicated page Link