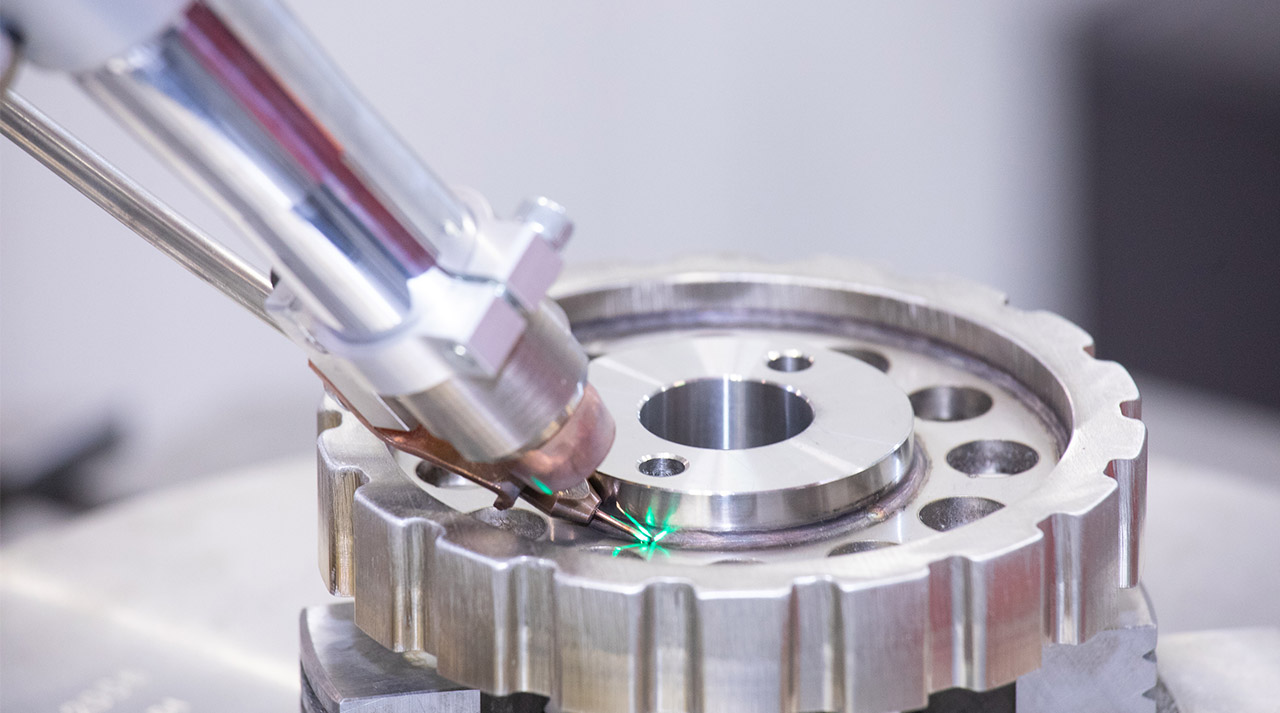

AMADA je lider u tehnologiji ćelija za zavarivanje fiber laserom. FLW-ENSISe ćelija za zavarivanje ima mnoštvo osobina koje je čine jedinstvenom u pogledu kvaliteta zavarivanja, brzine zavarivanja i produktivnosti. Osnovna konfiguracija ćelije sastoji se od AMADA-inog sopstvenog fiber-laser izvora, 6-osnog robota na linearnim šinama, rotirajućeg stola koji se naginje i kabine za aktivnu bezbednost. Zavisno od nivoa proširenja, dopunske korisne funkcije mogu biti dodate.

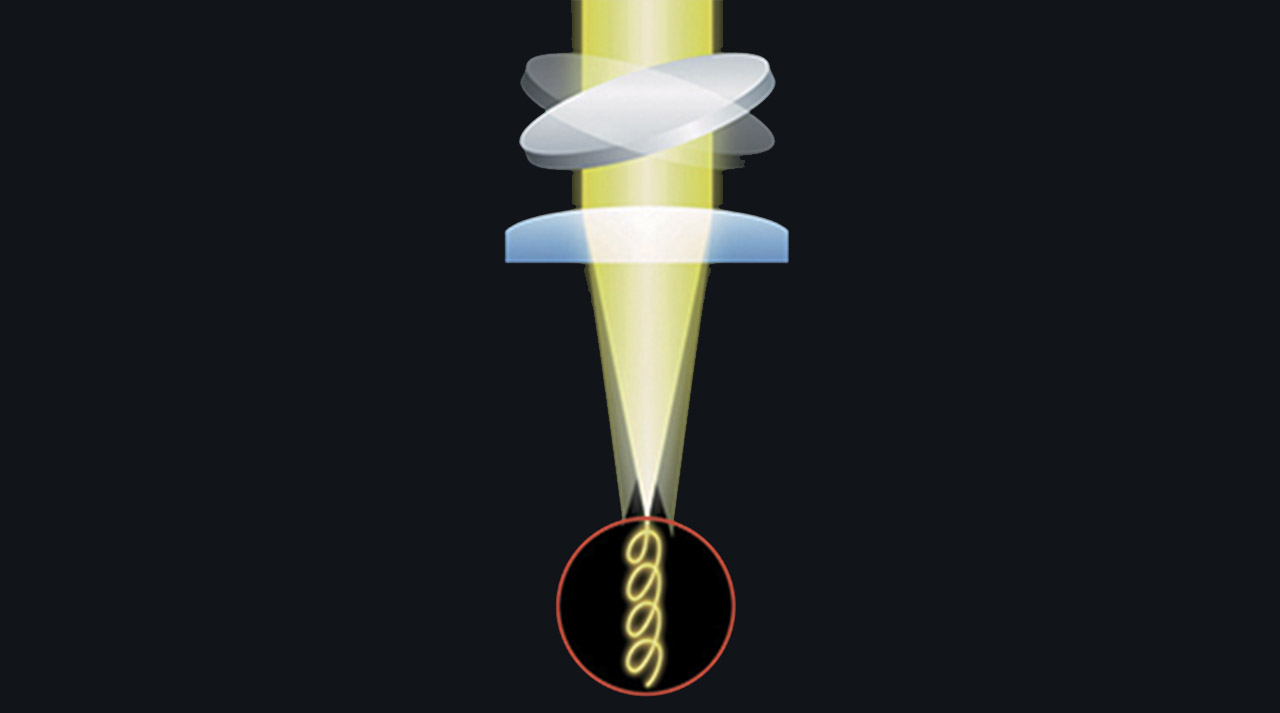

BEAM WEAVING:

This unique system rotates the actual laser beam using a weaving lens, rather than relying on a rotational motion of the robot, to allow much wider gaps to be cleanly welded. This results in much smoother, consistent welds and a higher quality part.

CHOICE OF POWERS:

The FLW-ENSISe solution can be supplied with 3kW or 6kW of welding power to provide the most suitable level of welding capability for your production

WELDING WIRE FEED:

For certain tasks, the supply of welding wire can be activated at any time. This can be varied even within a part and also helps to bridge larger gaps, which cannot be covered even by the beam weaving process.

| FLW-3000ENSISe M3 | FLW-3000ENSISe M5 | |

|---|---|---|

| Snaga lasera (W) | 3000 | 3000 |

| Tip mašine | Fiber laser | Fiber laser |

| Glava mašine | AMADA | AMADA |

| Hod po šinama (mm) | 3000 | 4000 |

| Maks. brzina po šinama (m/min) | 60 | 60 |

| Ponovljivost pozicioniranja preciznost (mm) | ± 0.1 | ± 0.1 |

| Maksimalna nosivost radnog stola (kg) | 500 | 500 |

| Osa rotacije radnog stola | ± 720 ° | ± 200 ° |

| Osa za naginjanje radnog stola | ± 90 ° | ± 90 ° |

Karakteristike robota: | ||

| Type | Vertikalno usklađen 6-osni robot | Vertikalno usklađen 6-osni robot |

| Upravljačka jedinica | YRC1000 | YRC1000 |

| Proizvođač | - | - |

Dimenzije: | ||

| Dužina (mm) | 7500 | 8500 |

| Širina (mm) | 5000 | 4500 |

| Visina (mm) | 3700 | 3700 |

| Težina (kg) | 13850 | 15265 |

Tehnički podaci mogu da budu drugačiji zavisno od konfiguracije / opcionih elemenata

Molimo vas da nas pozovete za više detalja i mogućnosti, ili skinite sa sajta našu brošuru

For your safe use

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1