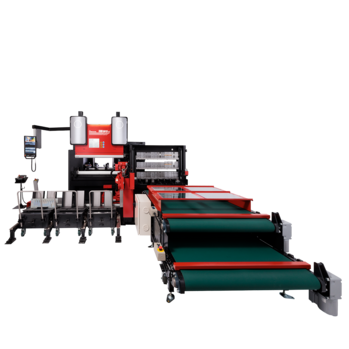

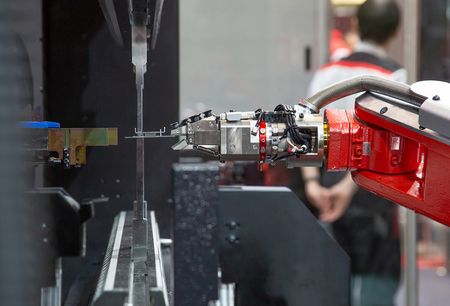

EGB-ARce is designed to revolutionize the production of small and complex components. By combining a next-generation servo-electric press brake with an advanced robotic system, this cell can autonomously manage the entire bending cycle with maximum efficiency and minimal need for specialized operators. The result is a significant increase in productivity—even on hard-to-make parts—with consistent quality and shorter lead times.

MORE CAPACITY, MORE TOOLS, MORE BENDING POSSIBILITIES

EGB-6013ARce stands out for its increased load capacity and optimized cycle time, allowing new parts to be loaded while the cell is operating. The automatic tool changer (ATC) capacity has been boosted by 35%, enabling a wider range of operations, including parts of various sizes, complex bends, flattening, and offset processes. The gripper range and tool library have also been expanded to maximize flexibility.

DESIGNED FOR COMPLEX COMPONENTS AND VARIABLE BATCHES

While it excels with small and intricate parts, EGB-6013ARce can handle components up to 550x300 mm, with a maximum thickness of 6 mm. A 10 kg payload robot and a 3.2-meter beam ensure flexibility and autonomy, even for medium-sized production runs. Efficient loading/unloading is ensured by double-layer conveyors and optimized accumulation areas—key to total efficiency.

SMART AUTOMATION MADE EASY

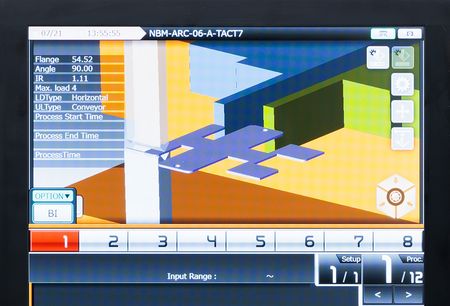

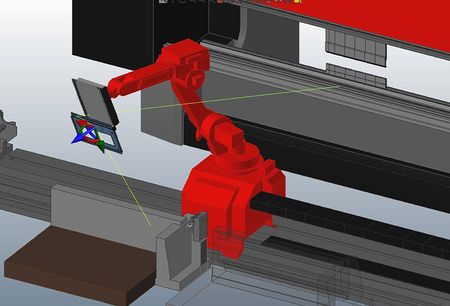

EGB-6013ARce is built around a simple concept: making human-machine interaction easier. With the new tabletop HMI tablet and automatic teaching mode, even non-specialized operators can manage the cell with ease. At the same time, the AMNC 4ie control system—integrated with VPSS 4ie ARBend software—enables automatic production programming, optimizing movements to minimize cycle times. Programming becomes quick, intuitive, and precise, even for complex cycles.

AN INVESTMENT FOR THE SMART FACTORY

With EGB-6013ARce, AMADA delivers a complete solution for tomorrow’s smart factory. Manufacturers can produce complex parts faster, with consistent quality and lower costs—even during unmanned shifts. This is technology designed to boost competitiveness and reduce inefficiencies through advanced automation.

Find out more on the dedicated page [link]