ORSUS-3015AJe is AMADA’s solution for companies looking to build a solid foundation for their first step into the world of high-speed, high-precision laser cutting. With available power options ranging from 3 to 8 kW and a wide range of advanced technologies and features, it is the ideal starting point for any business and can adapt to a variety of production environments. The ORSUS-3015AJe comes fully equipped with numerous features designed to enhance cutting quality, reliability, and ease of use: the Automatic Mode Converter, the Laser Integration System (LIS), the latest-generation AMNC 4ie control, compatibility with V-factory and IoT, Mobile HMI, and more.

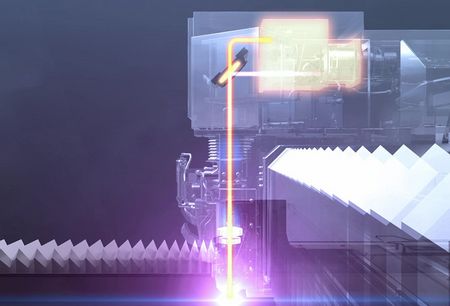

The Automatic Mode Converter seamlessly switches the laser beam from a highly focused beam—used for piercing and cutting thin materials—to a wider and more stable beam for thick sheet processing. This transition is instantaneous and automatically managed by the laser, allowing it to switch between piercing and cutting modes, fully leveraging both beam types for any material. In addition, a single focusing lens can be used for the entire material range.

ORSUS-3015AJe includes a suite of LIS system features from AMADA, such as an automatic head collision detection system and the i-Optics sensor to monitor protective glass wear. Also included is i-Process Monitoring, which detects errors during cutting or piercing and attempts to correct them without halting production. Flexibility is key—ORSUS-3015AJe is compatible with most AMADA automation solutions, both factory-installed and retrofittable. This means it can be configured to meet the production needs of a wide variety of industrial sectors and can easily adapt to changes over time.

The latest-generation AMNC 4ie numerical control is designed to be intuitive and fast. The new “maintenance guide” mode supports less experienced operators in daily tasks, while the updated machine history tool shows data on efficiency and energy consumption. Another feature is the i-Camera Assisted System (i-CAS), where the internal camera takes a snapshot of the sheet on the cutting bed and automatically nests parts in the available space—or allows the operator to move, rotate, and place them using the touchscreen. The AMNC 4ie is also compatible with AMADA’s Mobile HMI, allowing remote monitoring of the machine through internal cameras and the alarm system, as well as remote programming and scheduling. The operator only needs to load the material and press “start.”

Remote assistance is also available, thanks to full compatibility with AMADA’s V-factory and IoT systems. V-factory enables the collection and analysis of production data, while IoT functions allow remote laser access to assist with troubleshooting and diagnostics, minimizing downtime. Backed by industry-leading service, software solutions, and spare parts availability, ORSUS-3015AJe is the ideal solution to help customers build a foundation for success.