Since its foundation in 2000, SSC Laser Cutting has grown to become a major UK force in precision laser profiling and fabrication, today operating across three manufacturing sites in Stafford, Derby and Bristol, with plans to expand in the north east and north west. Markets served include street furniture, pharmaceutical, retail, marine, rail, architecture, construction, automotive, agriculture and oil and gas, to list but a few.

Although using an array of AMADA press brakes, including two HFE-130 M2 tonne machines, a HFE-8025 tonne model, and a HD-1703 long-stroke machine, until recently SSC had been restricted by the use of basic CAD/CAM software.

“We’ve had AMADA press brakes for many years, and although we looked at other options, it was apparent that using AMADA software was the way to go, the software is designed for use with AMADA machines and is future-proofed accordingly. In addition, it handshakes nicely with many other software packages.”

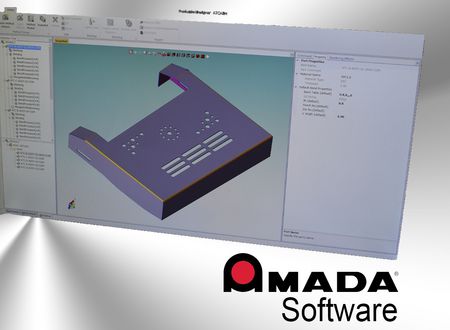

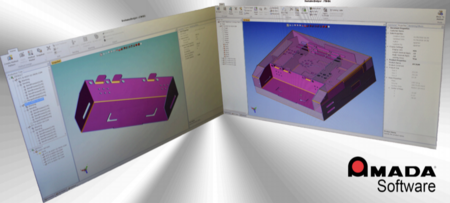

Following an in-depth analysis of the software, SSC purchased both AMADA’s Production Designer and VPSS 3i BEND for its headquarters near Stafford.

Both software suites work to reduce production time with their easy-to-navigate user interfaces and an array of automated functions that help minimise manual activities. The software further streamlines the press-braking process with a 3D simulation of the bend sequence and tooling set up.

SSC Laser Cutting now has three seats of Production Designer and VPSS 3i BEND, one for each production site.