Amada offers a variety of machines that incorporate both the patented dual servo motor punching technology and Amada's in-house designed 3kW fibre laser. Ideal for minimising secondary operations, meaning lower cost per part and increased profitability. Due to the fully electric punch and efficient fibre source the EML-AJ has low energy consumption and high productivity. Also available with full automation options.

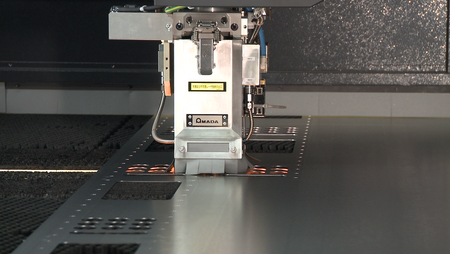

The EML-AJ uses a single module 3kW version of AMADA’s own in-house designed fibre laser oscillator, which is perfectly suited to the processing of combination parts with very low running costs. A wide range of materials and thicknesses can be processed with compressed air on the EML-AJ as standard. This drastically reduces the assist gas costs and leads to higher profitability. Cutting speeds are generally the same as with nitrogen

The EML-AJ uses twin AC servo motors to generate 30 tons of punching force, allowing a wide range of punched and formed parts to be processed. This system uses up to 70% less electricity compared to hydraulic systems. To compliment the already high capabilities of the EML-AJ machine, the Punch & Form (P&F) System is also included as standard. This consists of a 16 ton forming system which activates the die to allow the processing of forms up to 22mm high.

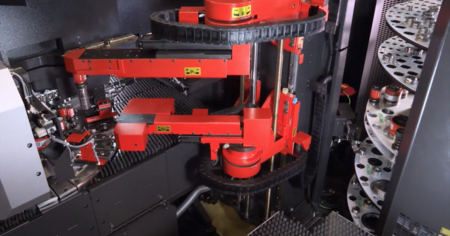

The EML-AJP version includes the PDC (Punch Die Changer) unit to minimise manual tool loading operations. Up to 220 punches and 440 dies can be stored in the system and all tool sizes can be automatically loaded / unloaded by the robot, including ‘E’ station tools and forming tools.

Using AMADA's in-house designed 3kW fibre laser engine and market leading servo electric punching technology, the EML-AJ provides the perfect tool to enhance your productivity. In order to provide the highest levels of operator protection, and to fully comply with CE marking regulations, an innovative table cabin design is utilized. Due to the front open concept, as with all AMADA fibre laser combination machines, a sheet of material can be loaded manually if required without opening the table cabin due to a second origin point in front of the cabin. Tapping stations, auto index stations and slug suction systems all contribute to a compact, highly flexible processing centre.

Recently launched at EuroBLECH 2022, the ASR-3015PR, the latest automation cell for punch/fibre laser combination machines was unveiled in the UK. The cell offers versatility and efficiency to production by combining material storage, parts picking and scrap handling in one single machine. The open front access to the combination machine lets you effortlessly load material, e.g. for rush jobs and prototyping. The ASR-PR will boost the productivity of the EML-AJ or ACIES-AJ combination machine considerably!