AMADA is pleased to announce that in 2023 we reached 200 VENTIS-AJ 4kW machines sold in Europe. The 200th VENTIS-AJ 4kW Fibre laser, which uses AMADA's unique Locus Beam Control technology provides performance similar to a standard 6kW solid-state laser.

Alongside the existing 4kW the new 6kW variant was launched at our manufacturing facility in France. This new higher power variant can provide similar performances to a 8-10KW standard laser.

Since its launch in late 2019, AMADA’s VENTIS-AJ 4kW fibre laser achieved its 100th order in November 2021. The landmark 200th order was received less than 15 months after this, highlighting the fact that European customers are embracing the benefits of LBC technology at an increasing rate. Achieving productivity similar to higher power machines, while using less power, has been a focus for customers over recent years, reducing the overall cost-per-part and making them more competitive.

RDS orders the 200th VENTIS-AJ 4kW

RDS (https://www.rds-tolerie-laser.fr/), based in Vernouillet near Dreux, France ordered the 200th VENTIS-AJ 4kW fibre laser in Europe and supplies various industrial sectors including construction, automotive, pharmaceutical, food and aerospace. They currently have AMADA bending and shearing machines. The VENTIS-AJ 4kW is their first AMADA laser, replacing a competitor’s machine to increase overall efficiency.

The new 6kW version debuted two new technologies for laser processing:

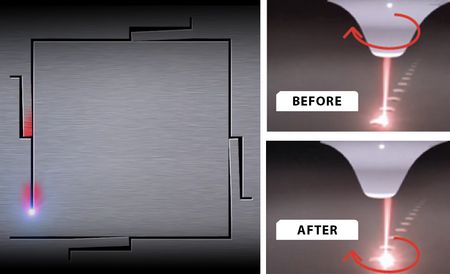

LBC FLASH CUT allows cutting of small holes independent of the machine drive system. The LBC unit creates the circular motion, which drastically increases the number of holes that can be processed per second.

SOFT JOINT technology is a completely new method to hold parts in a metal sheet, using the material stress to clamp the parts in place. This significantly reduces part tip-up possibilities and provides much more reliable processing of smaller parts.

The 6kW VENTIS-AJe is equipped with the new AMNC 4ie control. Designed specifically to make machine operation more intuitiveand rely less on highly skilled operators, the new control has several new functions.

Facial recognition can automatically change the language used to one of 15 stored on the control, whilst reducing work processes and improving work efficiency.

Automatic remnant nesting also improves material utilisation, whilst the Mobile HMI feature allows multiple machine data to be analysed remotely.

Maintenance tutorial videos can also be viewed on the control, or transferred to a mobile device to allow operators to complete tasks that require them to move around the machine.

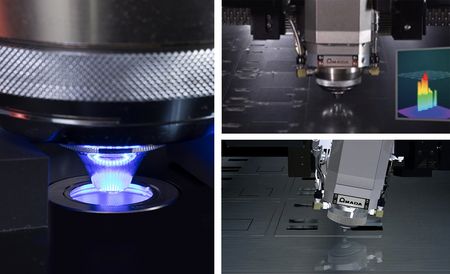

The VENTIS 6kW is fitted with the full suite of AMADA’s LIS (Laser Integration System) to give more autonomous production. Functions such as automatic beam to nozzle centring, protection glass monitoring and automatic head collision recovery allow the machine to run longer with less operator intervention.

With the ability to process thick mild steel of different grades without any cutting data amendments, produce stainless steel parts without dross and cut aluminium at the same speed as 10kW standard fibre laser machines, the VENTIS-AJe 6kW opens new opportunities whilst consuming less power.