AMADA's Locus Beam Control (LBC) technology, unique to the VENTIS-AJ Series, has the ability to manipulate the laser beam pattern whilst processing. Creating possibilities never before accomplished with solid state laser cutting machines.

LBC technology is an innovative system for controlling the laser beam motion. It manages beam patterns during the cutting process. The geometry of this pattern is variable for each thickness and material to be processed. The power of the beam no longer needs to be diffused to cut any materials. This means you get very high processing speeds and remarkable cutting quality.

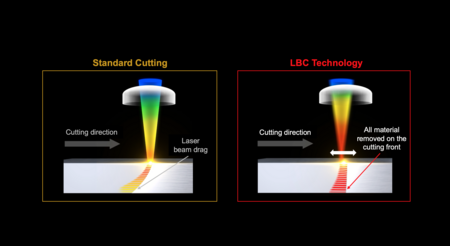

Laser cutting involves melting the material with a laser beam from the top surface and removing the molten material with assist gas. Standard laser cutting requires higher and higher power if the required speed is increased. Otherwise material cannot be removed efficiently, potentially leading to cutting failure.

With LBC Technology, the optimal beam pattern is used to remove all the molten material quickly and effectively from the cutting front, enabling speeds equivalent to higher power lasers. This leads to increased productivity and lower cost-per-part.

The heat generated by the laser beam reduces as it gets further from the top surface of the material, therefore, there is not enough heat at the bottom of the cut to efficiently melt and remove the material. LBC Technology allows the high density laser beam power to be utilised across the side faces of the cutting kerf, providing sufficient heat at the bottom of the cut to give dross free possibilities.

Very high quality stainless steel and aluminium processing is possible, which significantly reduces or eliminates any secondary operations required after cutting.