AMADA are pleased to announce that, in December 2021, the 100th European order was received for the VENTIS fibre laser featuring the revolutionary Locus Beam Control (LBC) Technology, which allows the 4kW VENTIS to perform like a 6kW fibre laser, as well as bringing cutting quality improvements. Lang Gerätetechnik GmbH placed the order for the laser with a twin tower version of AMADA’s ASF-EU automation system.

This milestone order has been achieved in only 2 years from the initial launch of the VENTIS, proving that LBC Technology is allowing many new and existing customers to expand their competitive offering. AMADA’s VENTIS-3015AJ is the first fibre laser cutting machine to feature the company’s LBC Technology, which improves both processing quality and productivity. In combination with a newly developed, high-brightness, single diode module 4kW fibre-laser oscillator, LBC technology sets a new world standard for laser profiling.

With the view to upgrade their laser cutting capabilities, Lang Gerätetechnik GmbH, based in Germany, investigated the market and the decision was made in favour of AMADA VENTIS fibre laser.

The company had several requirements when they made the decision to purchase the VENTIS fibre laser from AMADA:

Significant energy savings vs CO2 lasers, processing speed and the ability to increase the material thickness and types (copper and brass). The decision in favour of the VENTIS was made among other things because of the price-performance ratio vs other manufacturers 6kW fibre lasers and the fact that the LBC Technology provided a far more flexible production machine. Cutting speed and quality were also impressive vs higher power machines.

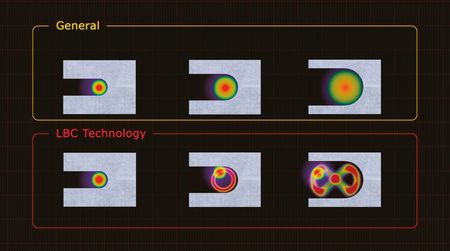

In conventional fibre laser, energy density reduces as material thickness increases, leading to a lack of efficiency and the need for defocussing the beam. Conversely, the use of LBC Technology, which is a world first for the laser-cutting market, offers flexible beam pattern control matched to each application, while retaining high-efficiency cutting and high energy density. Defocussing is therefore no longer required. In short, LBC Technology can freely manipulate the laser beam to create an infinite number of locus patterns that are advantageous to cutting performance.

For manufacturers of conventional fibre-laser systems, the only way to negate the loss of energy density is to increase the power output of the laser oscillator, but this comes at a cost, both in terms of purchase price and greater electrical consumption. In contrast, the VENTIS, with its specially developed, single diode module 4kW oscillator and LBC technology can reduce electricity bills by 30%.

In Productivity Mode, users can realise a significant improvement in throughput when cutting with nitrogen. For instance, when processing stainless steel, the VENTIS with LBC technology will prove twice as fast as using a conventional 4kW fibre laser cutting machine, while aluminium will be 2-3 times faster. These performance levels, in tandem with lower energy consumption, can reduce processing costs by up to 75% in some instances.

Quality Mode, as the name suggests, can improve surface roughness by approximately 50% when compared with a conventional machine, while dross is minimised to less than 10μm. Recent trials at AMADA’s facility in Japan showed 15mm stainless steel to be dross-free after cutting. This outcome means that users can eliminate secondary operations such as deburring and reduce processing costs. Moreover, even though operating in Quality Mode, the trial was run at a cutting speed faster than a standard 4kW fibre laser cutting machine.

Finally, Kerf Control Mode enables long-term stable processing during automated system operation. The kerf width can be expanded to 2.3 times wider than general fibre lasers due to the use of LBC Technology. In fact, the system is able to control kerf width for optimal efficiency based on the material type and thickness being processed. The result is consistent part removal and long, stable processing during operation.