The market increasingly demands flexibility and efficiency from companies, making production planning complex, often subject to continuous re-scheduling. It is therefore essential to find solutions that can ensure a stable and continuous flow. AMADA is always careful to the current market demands and is ready to offer the most innovative answers to allow companies to produce in a highly performing way, using automated systems that help to solve the critical issues hidden in the production phases, from cutting to bending

AMADA products

The AMADA product range for bending goes from stand-alone systems to the most complex robotic cells, always ensuring the typical reliability and ease of use with innovative tooling solutions, bending process automation systems and dedicated software. Also as regards the laser cutting, AMADA offers solutions suitable to meet every specific application need: analysing the production cycle and individual needs, in fact, AMADA can offer the most performing tool to optimize the processing and consequently grow the business of companies

Whatever the production area, automation has become a key and indispensable factor: process stability is as important as the performance of the single machines. The automation solutions offered by AMADA are specifically designed to cover all areas of production, starting from cutting: automatic pallet changing systems for lasers, single or double tower warehouses, the TK sorting system up to the flexible and fully configurable CS II production system. These automation systems are essential to ensure a truly efficient use of laser technologies, punching machines and combined machines.

Automation is also synonymous with flexibility: the automatic tool change system designed forATC press brakes, for example, has been specially developed to ensure production continuity even in the face of constant changes in processing, dictated by market urgencies. Among the benefits of automation is the opportunity to balance production flows: this often allows to adopt solutions of lower power, also allowing less frequent maintenance, due to less wear of the components.

From cutting to bending, automation allows you to manage an entire process using AMADA software VPSS3i. Once the 2D or 3D file of the product has been imported, VPSS 3i creates the development, calculating all withdrawals according to the tool setup and also defining the bending program. Next steps concern the nesting on the sheet and the calculation of the cutting parameters according to the material, continuing with the actual production.

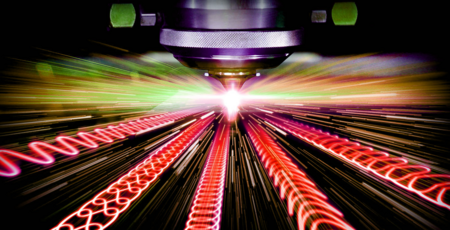

AMADA VENTIS-AJ 4kw technology with Locus Beam Control can manage the geometry of the laser beam path during cutting and choose the most suitable one depending on the machining characteristics. VENTIS-AJ allows in fact to operate in productivity mode, synonymous with a technology that prioritizes the cutting speed, in quality mode, for a cleaner cut without slag, therefore without the need to perform further post-cutting manipulations on the workpiece. Finally, in kerf-control mode: option that generates wider cutting grooves to facilitate automatic sorting operations, especially on smaller sheets.

The TK system also allows the unloading of parts even of complex shapes thanks to an innovative management of independent suction cups and a control system for the correct removal of the piece. All programming is managed off-line via VPSS 3i and is optimized specifically to be easy to use, while ensuring high precision stacking of the parts produced.

Finally, cut and stacked parts can be bended by HRB-ATC: by means of a special QR Code, laser marked on the workpiece by VENTIS-AJ during the cutting phase, the operator can, using a special scanner, read all the necessary information to recall the bending program and the correct setup. Thanks to this system, the machine can perform a self-setting, completely eliminating the possibility of human error and thus completing a fully-automated production process.