AS-III

More

The EM-MIIe range features an unrivalled 30 ton dual servo electric motor punching system and AMADA’s industry leading tool turret which is available in two different configurations (Z and K versions). These features provide quicker, superior quality processing.

The optional tool identification systems and dedicated tapping units reduce setup times and allow for even more process integration for higher efficiency.

VERSATILE TURRET:

The Z turret uses different diameter upper and lower disks, allowing dies to the quickly and easily changed. The K turret accommodates a large range of tools, reducing the number of tool changes required.

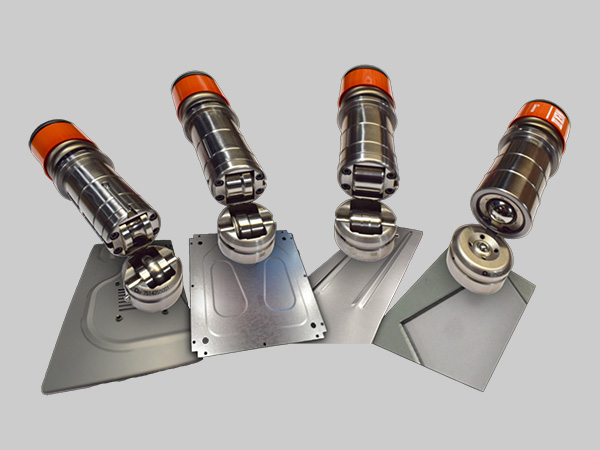

AMADA RAPID FORMING TOOL COMPATIBILITY

Complex forming operations such as offset joggles, chamfers and beading can be achieved in-cycle utilising the AMADA Rapid Forming Tool solutions.

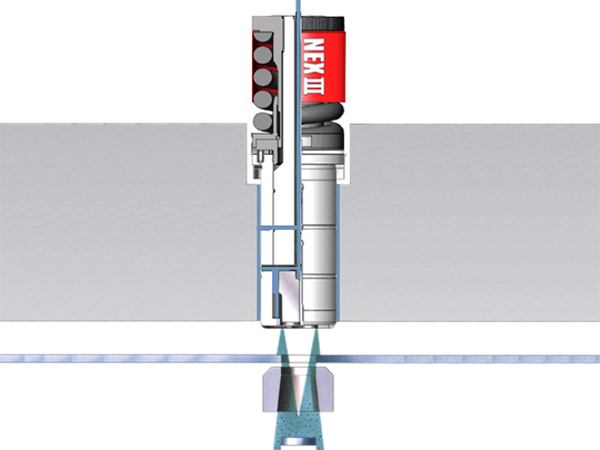

AIR BLOW SYSTEM

The programmable Air Blow function on the EM-MIIe allows for self lubrication of the punching tools to give the benefits of prolonged tool life and increased punching efficiency.

| EMZ-3510 MIIe | EMK-3510 MIIe | EMZ-3612 MIIe | EMK-3612 MIIe | |

|---|---|---|---|---|

| Z Turret | K Turret | Z Turret | K Turret | |

| Number of stations | 44 MPT or 45 stations (4 AI) | 55 MPT or 58 stations (4 AI) | 44 MPT or 45 stations (4 AI) | 55 MPT or 58 stations (4 AI) |

| Press capacity (kN) | 300 | |||

| Drive system | AC servo, direct twin drive | |||

| Punching accuracy (mm) | ± 0.1 | |||

| Axis travel distance (mm) | 2500 x 1270 | 3050 x 1525 | ||

| Machine frame | Bridge frame | |||

Dimensions | ||||

| Length (mm) | 6157 | 6582 | ||

| Width (mm) | 5120 | 6220 | ||

| Height (mm) | 2367 | 2367 | ||

| Weight (kg) | 19000 | 19500 | 21000 | 21500 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.