Sheet metal processing has always been a hyper-competitive market. Today, manufacturers are subject to ever tighter times, halved batches than they used to be and demands for agility that require very short-term planning. In addition, managing this situation requires the ability to process large quantities of materials ensuring speed and quality.

Those who produce machines for sheet metal processing must make their own the needs of the market and ensure, thanks to increasingly advanced and effective technological solutions, the best balance between versatility, quality and speed. With the addition of an additional factor: the simplicity of use, the only element of contrast to the phenomenon, sadly known, the skill gap. This involves the interconnection of machinery, interfaces, ergonomics, UX and, more generally, automation and process optimization.

REGIUS-AJ, a convincing response to market challenges

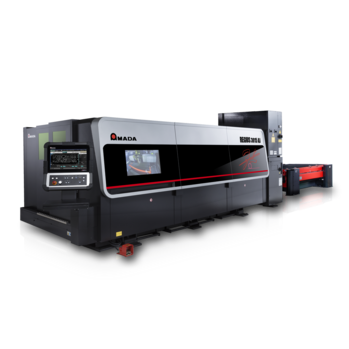

Among the machines able to best integrate in a highly competitive market, REGIUS-AJ occupies a privileged position. This is the most recent and advanced generation of AMADA laser cutting machines, which has all the brand’s experience and focuses on a series of innovative factors that can directly affect productivity, efficiency and, in fact, the simplicity of production. All this, of course, without neglecting in any way the quality factor, which AMADA proprietary technologies guarantee no compromises.

REGIUS-AJ is a fiber laser cutting machine based on the AMADA proprietary generator, available with 6kW, 9kW and 12kW power depending on the specific cutting needs. It is the fastest machine within the AMADA range, the most recent in terms of market introduction and is also a true concentrate of technology aimed at addressing the above challenges.

REGIUS-AJ: technologies that improve productivity

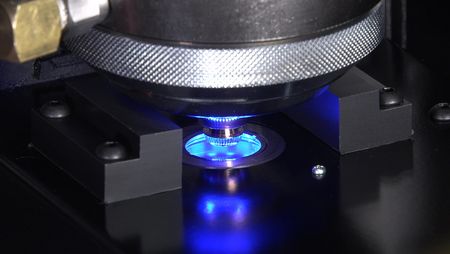

The very high cutting speed and precision result from a clear synergy between engineering and technological choices.

In particular, speed is affected by the 3-axis linear drive technology, based on motors designed by AMADA. Using magnetic force and acceleration up to 5 g, these keep consumption down and enable combined X/Y positioning speeds of 340 m/min, reducing cycle time.

Productivity is also affected by the intelligent cutting head control technology, another primary feature of the REGIUS-AJ series. It is, in practical terms, a technique that optimizes the movements of the machine according to the analysis of subsequent operations. In an era of ever-changing operations and tight customer demands, smart technologies like this can really make a difference.

Last born of a winning family

REGIUS-AJ takes advantage of all the technologies that are the basis of the productivity and efficiency of AMADA products.

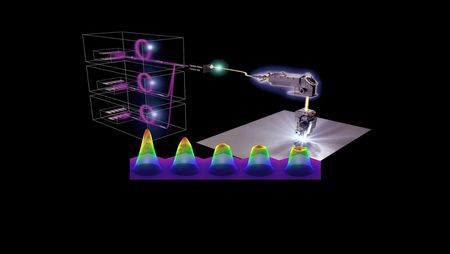

One example is ENSIS technology, with variable laser beam control. Available since 2014 and subject to a continuous improvement path, this allows to continuously modulate the laser beam according to the processes to be carried out, ensuring at least three benefits: versatility, instant change of the mode and use of a single lens for all the materials that can be processed by the machine.

On the same wavelength, then, lies the technology of automatic collimation, which through very precise controls on the spot size and the focusing of the beam, allows increasing the accuracy and perpendicularity of the cut, as well as promoting the removal of molten material. Adding up the ECO Cut technology, the 9kw version of REGIUS-AJ is able to pierce a 25mm iron surface in 1 second.

Automation of the Laser Integration System

As anticipated, REGIUS-AJ was born with the specific intention of creating a competitive advantage in particularly challenging market conditions, and there is no doubt that several factors, including automation, contribute to this objective.

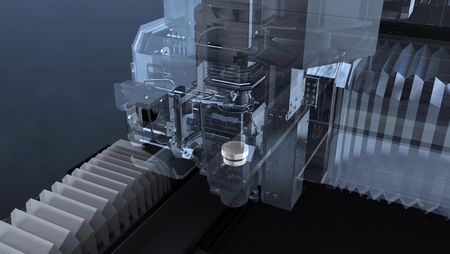

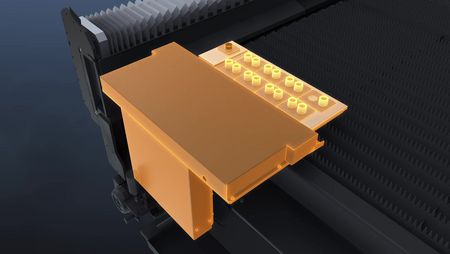

In REGIUS-AJ, we have therefore introduced a Laser Integration System (LIS) as a sum of several automatic solutions whose aim is to maximize the efficiency of the machine requiring a contained intervention by operators.

LIS is the concentrate of technology mentioned above. It includes an automatic nozzle change function on 16 stations, but also performs:

The aforementioned features, together with the Automatic Collision Recovery for automatic nozzle replacement in the event of a collision, enable a general acceleration of operations, as well as a significant saving of time when starting the machine, where in fact various preparatory operations are performed to its operation.

Last but certainly not least, REGIUS-AJ is a simple machine to manage, which takes on repetitive and rule-based tasks allowing operators to focus on more value-added tasks.

Simplicity is affected by the AMNC 3i Plus numerical control with large touch screen. It allows you to rotate, move and zoom quickly and intuitively, promoting productivity and making the most of the available material. The integration of the i-Camera Assisted System (i-CAS) should also be noted: REGIUS-AJ, in fact, integrates a camera that allows the operator to immediately view the sheet, select a geometry from the AMADA database and automatically set the cutting program by dragging it onto the image taken by the camera itself. In this way, besides optimizing the user experience (UX), it also significantly improves the nesting capacity on the residual material.

.

Finally, REGIUS-AJ is compatible with different automation systems, allows remote control via tablet through V-Remote functionality and, above all, can be integrated into the AMADA smart ecosystem, whose aim is to make the most of innovation to optimize production processes in their entirety.