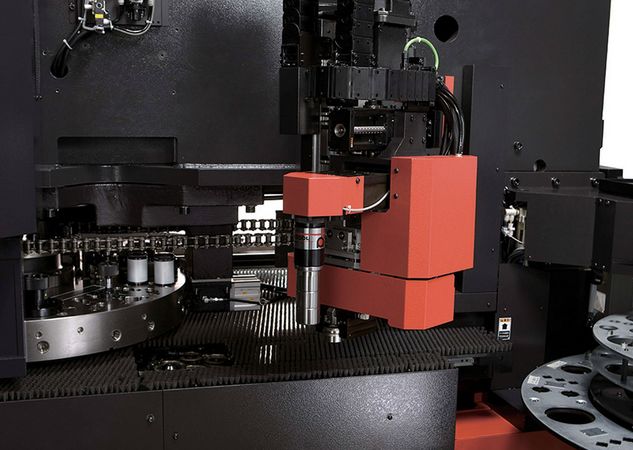

VENTIS-AJe 9 kW

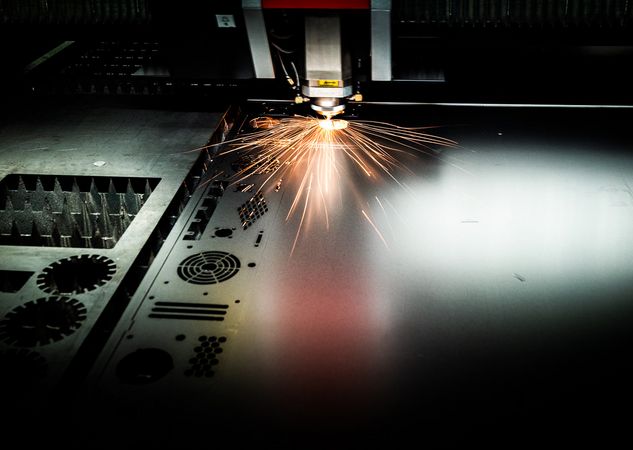

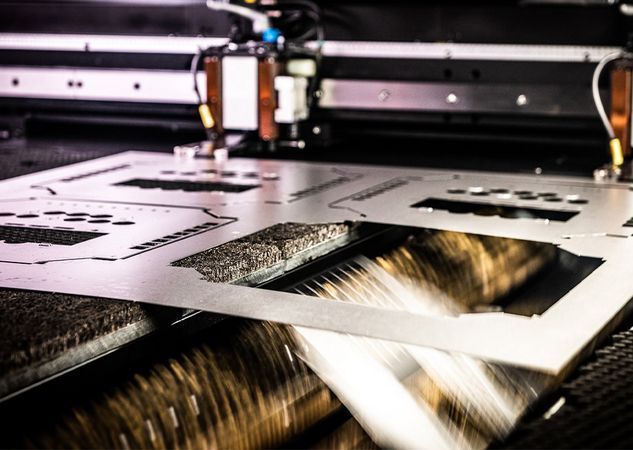

The new VENTIS-AJe 9 kW laser cutting machine takes AMADA's technological innovation to the next level.

MoreIn a continuously changing world, it is important to remain updated and keep up with the times.

That is why - in this section - we offer you all the latest news in the field of sheetmetal working and in the world of AMADA.

Innovations, trends, corporate and local initiatives: read our latest news to find out all of this and much more.

The new VENTIS-AJe 9 kW laser cutting machine takes AMADA's technological innovation to the next level.

More

If you want to ensure strong, aesthetically refined, and defect-free welds, it all starts here: with the quality of the bend. And to achieve these standards, you need to rely on cutting-edge solutions that combine precision, automation, and ease of use.

More

In the world of sheet metal processing, digitalization is not an option—it is a necessity

More

Our mission is clear: to build a sustainable, secure, and efficient future together

More

AMADA'S revolution reduces consumption and increases productivity

More

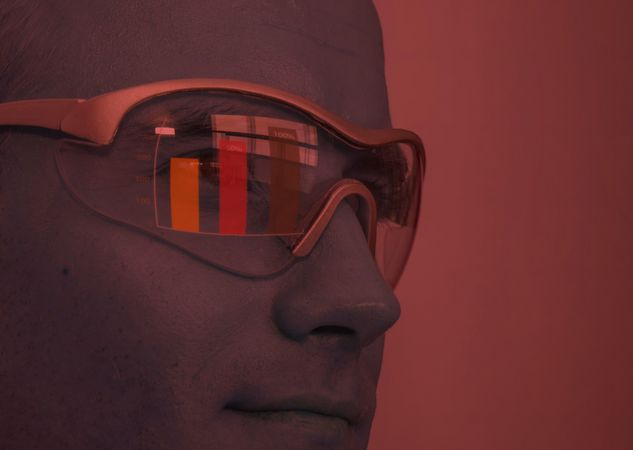

Industry 5.0: the fifth industrial revolution. This new challenge, a natural evolution of the technological transition brought by Industry 4.0, aims at a "Collaborative Industry", a model that focuses on the individual and the environment, through incentives aimed at promoting more sustainable production processes from all points of view: ecological and social

More

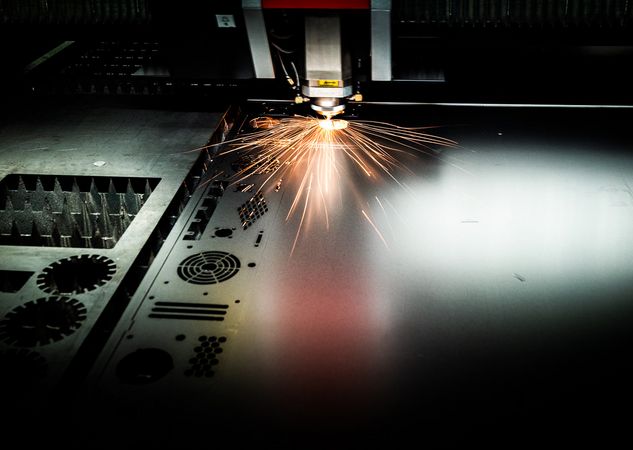

ENSIS-AJ, REGIUS-AJ, VENTIS-AJ: the latest laser generation, for unparalleled machining quality. Discover the added value of laser technologies: operational simplicity and maximum precision.

More

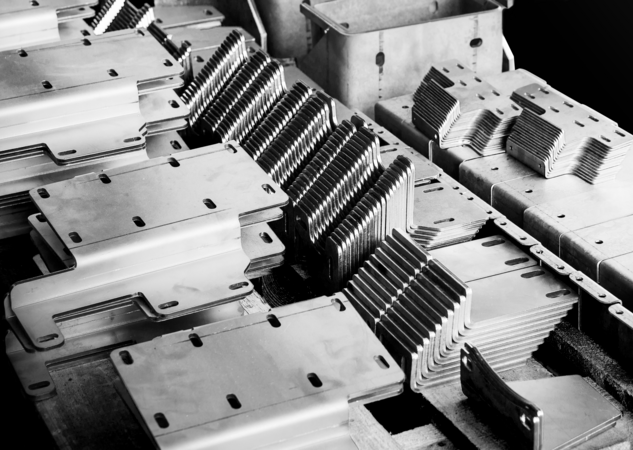

HRB-5020, EG-4010, HFE3i-5020: the ideal solutions for every production.

More

Designing sheet metal parts has never been so simple and functional, thanks to SheetWorks by AMADA: the 3D parametric solid model, that allows designing assembled parts, convert them into sheet metal and process their development automatically, optimizing the entire production process.

More

The latest addition to a family that has been able to overcome every challenge in sheet metal cutting, the brand new REGIUS AJe 12 kW is today the most efficient and reliable answer to the increasingly demanding requests of the market.

More

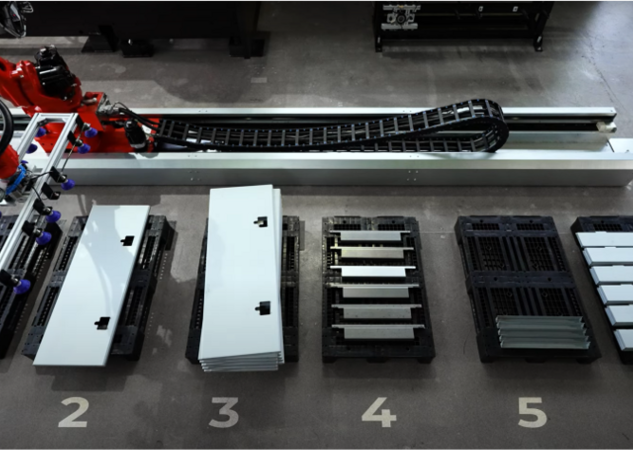

Many customized solutions to make your production cycle more efficient and safe in all sheet metal processing, from Blanking to Bending.

More

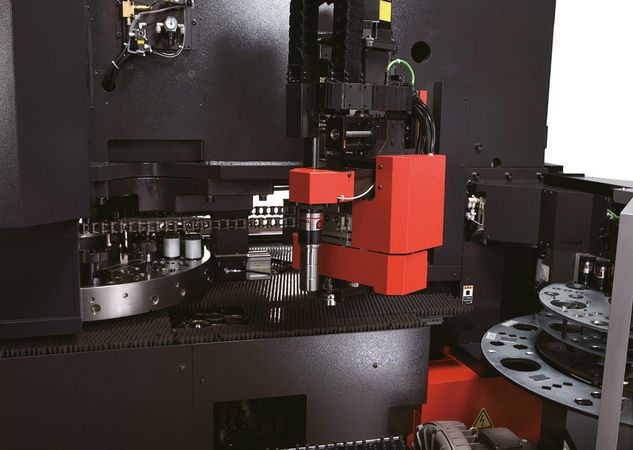

HG-ATC and HRB-ATC automated technologies can reduce setup times and increase the productivity of your company.

More

Making AMADA production management and machines dialogue has never been so simple: AMADA ORDER MANAGER is the innovative cloud system from AMADA that allows you to transform your company into a Smart Factory

More

Performance and Maintenance - With the AMADA service you can find the ideal solution for every production need: a highly specialized team and the latest technologies always available, everywhere.

More

The AMADA bending machine responds to the challenges of the sector by guaranteeing speed, process simplification and quality of the result.

More

AMADA’S innovative solutions for an increasingly efficient and versatile production

More

AMADA bending machine responds to the challenges of the industry by ensuring speed, simplification of the process and quality of the result.

More

AGIC was born to solve the numerous issues faced by customers around the world, including their demands for “support for new materials and processing technologies”, “improvement of automation and productivity,” and production innovation.

More

Thanks to the interconnection of machinery and data enhancement, V-factory enables remote monitoring and advanced support activities

More

Optimizing productivity means adopting a systemic vision of the entire production process, exploiting synergies and automation

More

Thanks to AMADA Order Manager it is possible to create a connected production ecosystem, from the business level (ERP) to the factory

More

REGIUS-AJ responds to the challenges of sheet metal processing with speed, versatility and quality: here’s how

More

IoT Support enables enterprises to reduce and prevent downtime, maximizing productivity and efficiency.

More

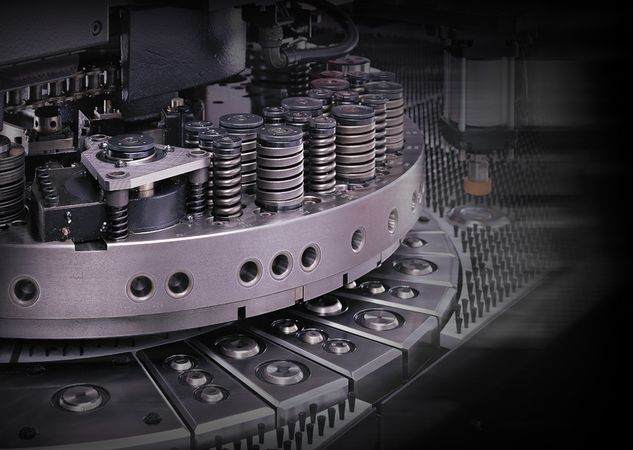

Speed and continuous operation are some of the benefits of laser-punching combination machines. AMADA EML-AJ is an eloquent example.

More

From online courses to remote support, here’s how to update the skills of your resources, preparing them for the challenges of tomorrow

More

Relieving people from stressful activities and making the most of the human machine synergy. These are the trends of industrial automation

More

HRB-ATC guarantees high performance, the use of the latest technology, safety and sustainability

More

Less injuries, more comfort and well-being: how technology 4.0 helps achieve these goals

More

In the era of Industry 4.0, data analysis is - or should be - the main decision support tool.

More

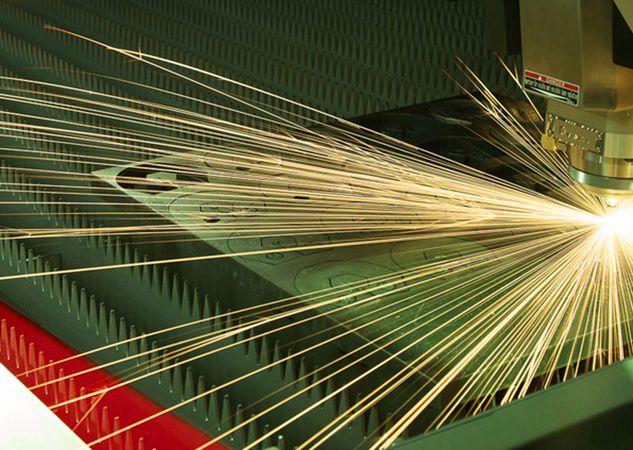

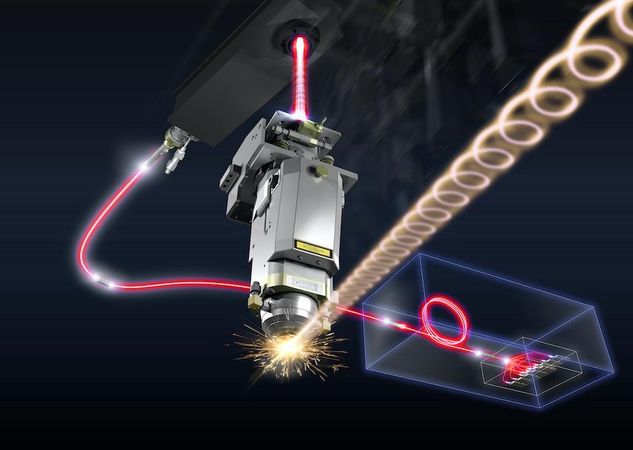

The exponential increase in laser power is accompanied by technologies dedicated to increasing speed, quality and savings

More

From predictive maintenance to industrial process optimization: how AI perfects the smart factory

More

The new ENSIS fibre laser series has been expanded to incorporate 6.2 x 2.5 metre capabilities and provide you the best technology ever!

More

In sheet metal bending, the skill gap is very pronounced. Machines like AMADA HBR-ATC help reduce it. Here’s how

More

Laser cutting and automation work in symbiosis to improve cutting quality, speed and production process efficiency

More

The quality of laser cutting depends on the quality of the source and the ability to control the beam, which many AMADA technologies are aimed at.

More

A factory connected according to the Industry 4.0 model enables remote monitoring of assets and processes. Industrial Smart Working is a reality!

More

High machine performance, automatic setup and offline programming make sheet metal bending tasks efficient. Learn more.

More

Let’s discover together the role of Assist Gases, that is the Assist Gases to the cutting process, and their impact on essential parameters of productivity, production speed and reduction of operating costs.

More

Machine downtime, waiting for the technician and spare parts are just a memory: thanks to the laser head repair kit you can intervene quickly and independently!

More

Although it has always been a cornerstone of sheet metal processing, the punching machine has undergone a strong process of innovation. Let’s see how.

More

Industry 4.0 is based on the concepts of interconnection and data enhancement, very dear to AMADA and its V-factory system. Let’s see how.

More

Laser cutting is a cornerstone of sheet metal working processes: it ensures precision, speed, reduced consumption and maximum versatility

More

Intelligent automation is one of the enabling technologies of the 4.0 model. What are your goals? Maximum efficiency and a new relationship between man and machine

More

Increasing production flexibility means having the right mix of tools, processes, resources and technologies. Here’s how to do it.

More

Cost reduction, productivity maximization, lead time acceleration and efficiency increase are just some of the promises of remote support services

More

Find out how to meet the challenges of a competitive market by optimising production cycles. Download our whitepaper now!

More

Predictive maintenance is a clear manifestation of the 4.0 industrial model or smart manufacturing. It has an important impact on cost, productivity and efficiency. Let’s see how.

More

Thanks to end-to-end virtualization and management of the production cycle, AMADA software ensures products of quality, speed of execution and security

More

The guys of the Team AUDACE of UniTS, sponsored by AMADA, were among the protagonists interviewed by Donatella Bianchi, for the broadcast of RAI 1, Linea Blu.

More

Reducing setup times, production costs, shortening lead times and working with less effort are some reasons to consider a machine with automatic tool changer

More

The project is ready for the official presentations: from 25 to 27 September the hull will be on display at Trieste Next!

More

Discover AMADA VOICE! The new AMADA Italia Telephone service has been available since 1st September.

More

The benefits of punching added to those of the laser: this is how combined machines for sheet metal processing are presented. We deepen the topic and discover the AMADA solutions.

More

Industry 4.0 is an innovative industrial model enabled by the latest generation of technologies. AMADA supports the 4.0 paradigm with advanced solutions, including the V-factory system

More

Accelerating machine setup is crucial to optimize production, reduce costs and lead time. AMADA offers solutions equipped with automatic equipment

More

We are sharing the information and directions necessary to reach us in the company, in compliance with current anti-Covid-19 measures

More

A meeting time and a confrontation with an expert, webinars are appointments that combine the convenience of usability from home with the possibility of interacting with our specialists.

More

Our consultants are ready to satisfy every doubt you might have, question or request, through remote consulting via call-conference

More

The courses are aimed at all our customers, those who want to "refresh" their know-how, those who want to update and those who have just purchased one of our products.

More

AMADA Italia’s Covid-19 Emergency Press Release – Updated on 23/03/2020.

More

From today the new AMADA website is online. It reflects the true essence of our brand and takes into account the customers' needs.

More

From 1st April, it will change its name to AMADA AUTOMATION EUROPE LTD, becoming a wholly owned subsidiary.

More

VENTIS is a new laser system equipped with the innovative LBC Technology (Locus Beam Control) launched by AMADA during the Open House on 22nd and 23rd November.

More

With AMADA V-factory it is possible to monitor data from the production lines anywhere and in real time, thanks to a simple internet connection.

More

On September 13th, our customers and stakeholders had the opportunity to visit AMADA's site in Pontenure and take part to one of our social events in the Gropparello's Castle.

More