ASR 3015 PR

More

The ACIES-AJ is the most advanced technology for punch/laser combination machines. Equipped with a 3 kW AMADA fibre engine, a 30 ton electric punching system and an automatic tool changer that holds up to 300 punches and 600 dies, the ACIES-AJ guarantees the utmost productivity and flexibility.

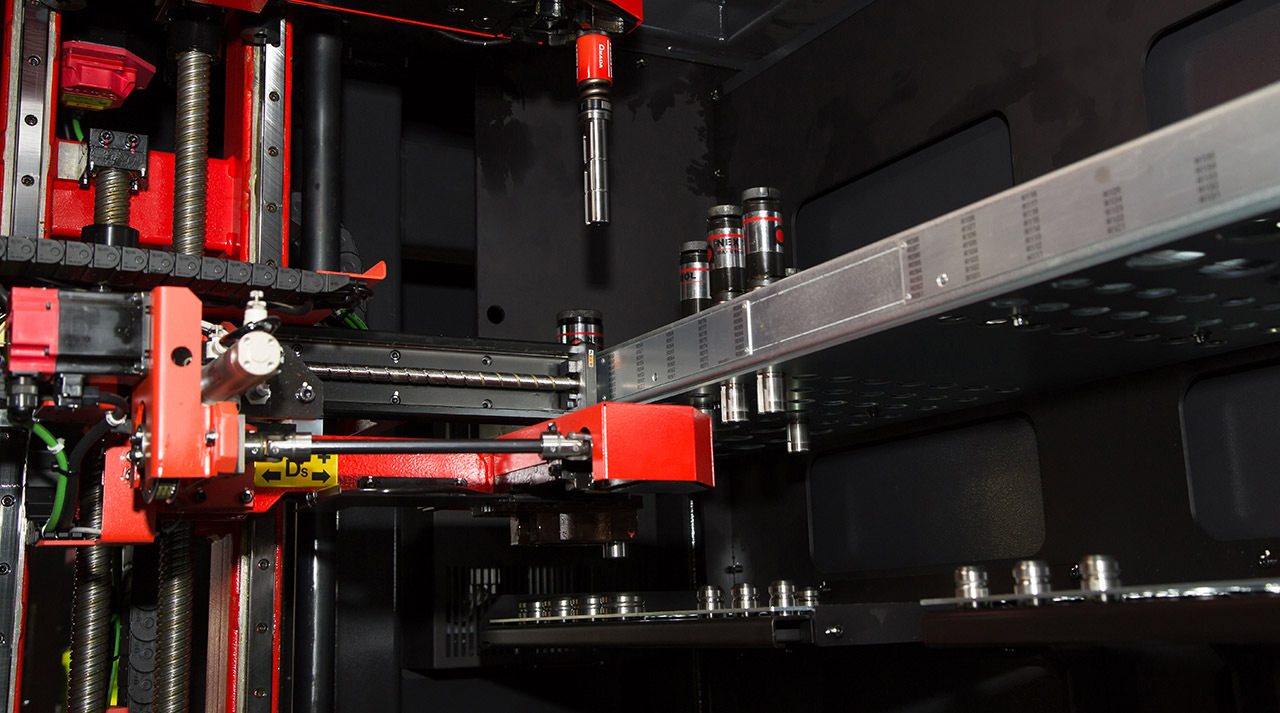

AUTOMATIC NOZZLE CHANGER:

To ensure continuous, automatic machine operation, the ACIES-AJ has a 4-station nozzle change system which includes a head calibration and nozzle cleaning unit.

TOOL STORAGE UNIT (TSU):

The TSU stores and automatically handles tools for the turret. This solution enables lengthy and continual processing cycles.

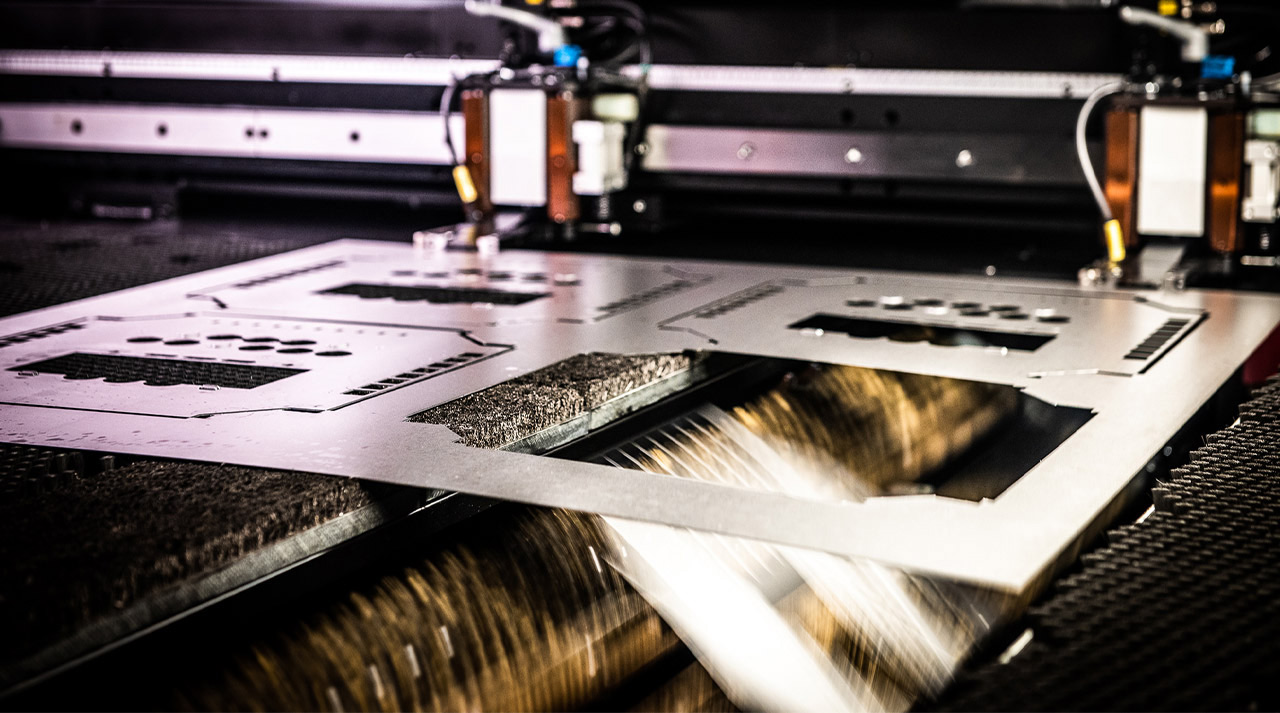

UNLOADING WORKCHUTE:

The large workchute (400 x 1550 mm) ensures the utmost efficiency in processing by allowing the elimination of micro-joints and easy removal of the part.

| ACIES-2515BAJ | ACIES-2515TAJ | |

|---|---|---|

| Press capacity (kN) | 300 | 300 |

| Laser power (W) | 3000 | 3000 |

| Machine frame | Bridge frame | Bridge frame |

| Punching accuracy (mm) | ± 0.1 | ± 0.1 |

| Table loading weight (kg) | 220 | 220 |

Simultaneous axis speed: | ||

| Punching X/Y (m/min) | 128 | 128 |

| Laser X/Y (m/min) | 141 | 141 |

Dimensions: | ||

| Length (mm) | 6242 | 7090 |

| Width (mm) | 6927 | 6927 |

| Height (mm) | 2524 | 2666 |

| Weight (kg) | 25700 | 29300 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1